Izinto ezenziwe ngengxubevange ezenziwe ngenhlanganisela eqinile yensimbi ephikisayo kanye nensimbi yokubopha ngenqubo yokusansimbi eyimpuphu. I-carbide esimende inezici eziningi ezinhle kakhulu njengokuqina okuphezulu, ukumelana nokuguguleka, amandla nokuqina okuhle, ukumelana nokushisa kanye nokumelana nokugqwala, ikakhulukazi ubunzima bayo obukhulu kanye nokumelana nokuguguleka, okuhlala kungashintshi ngisho noma izinga lokushisa lingu-500 °C, isenokuqina okuphezulu ku-1000℃. I-Carbide isetshenziswa kabanzi njengezinto zamathuluzi, njengamathuluzi okujika, okusika izigayo, ama-planer, ama-drill, amathuluzi okubhoboza, njll., ukusika insimbi ephothiwe, izinsimbi ezingezona i-ferrous, amapulasitiki, imicu yamakhemikhali, i-graphite, ingilazi, itshe kanye nensimbi evamile, futhi ingasetshenziswa futhi ekusikeni izinto ezinzima ukushiswa njengomshini njengensimbi engashisi, insimbi engagqwali, insimbi ephezulu ye-manganese, insimbi yamathuluzi, njll. Ijubane lokusika lamathuluzi amasha e-carbide manje seliphindwe kangamakhulu kunensimbi yekhabhoni.

Ukusetshenziswa kwe-carbide eqinisiwe

(1) Izinto zamathuluzi

I-Carbide iyinani elikhulu kakhulu lezinto zamathuluzi, ezingasetshenziswa ukwenza amathuluzi okujika, izigayi zokugaya, ama-planer, ama-drill, njll. Phakathi kwazo, i-tungsten-cobalt carbide ifanelekela ukucutshungulwa kwezinsimbi zensimbi nezingezona ezensimbi kanye nokucutshungulwa kwezinto ezingezona ezensimbi, njengensimbi ephonswe, ithusi eliphonswe, i-bakelite, njll.; i-tungsten-titanium-cobalt carbide ifanelekela ukucutshungulwa kwezinsimbi zensimbi isikhathi eside njengensimbi. Ukucutshungulwa kwezinsimbi zensimbi. Phakathi kwama-alloy afanayo, lawo anokuqukethwe kwe-cobalt okuningi afanele ukucutshungulwa okuqinile, kanti lawo anokuqukethwe kwe-cobalt okuncane afanele ukuqedwa. Ama-carbide afakwe insimbi ajwayelekile aphila isikhathi eside kakhulu ekucutshungulweni kwezinsimbi kunezinye ama-carbide afakwe insimbi ezintweni ezinzima ukucutshungulwa njengensimbi engagqwali.

(2) Izinto zokubumba

I-carbide efakwe usimende isetshenziswa kakhulu ezidayeni zokusebenza ezibandayo njengezidayeni zokudonsa ezibandayo, izidayeni zokubhoboza ezibandayo, izidayeni zokukhipha imfucuza ezibandayo, kanye nezidayeni zokufaka imfucuza ezibandayo.

Ama-carbide cold heading dies ayadingeka ukuze abe nokuqina okuhle komthelela, ukuqina kokuphuka, amandla okukhathala, amandla okugoba kanye nokumelana okuhle kokuguga ngaphansi kwezimo zokusebenza ezingagugi zomthelela noma umthelela onamandla. Amagreyidi e-cobalt aphakathi nendawo aphezulu kanye nama-grain alloy avame ukusetshenziswa, njenge-YG15C.

Ngokuvamile, ubudlelwano phakathi kokumelana nokuguguleka nokuqina kwe-carbide esimende kuyaphikisana: ukwanda kokumelana nokuguguleka kuzoholela ekwehleni kokuqina, kanti ukwanda kokuqina kuzoholela ekwehleni kokumelana nokuguguleka. Ngakho-ke, lapho ukhetha amamaki e-alloy, kuyadingeka ukuhlangabezana nezidingo ezithile zokusetshenziswa ngokuya ngento yokucubungula kanye nezimo zokusebenza zokucubungula.

Uma izinga elikhethiwe livame ukuqhekeka nokonakala ekuqaleni ngesikhathi sokusetshenziswa, izinga elinokuqina okuphezulu kufanele likhethwe; uma izinga elikhethiwe livame ukuguguleka nokonakala ekuqaleni ngesikhathi sokusetshenziswa, izinga elinokuqina okuphezulu nokumelana nokuguguleka okungcono kufanele likhethwe. . Amabanga alandelayo: YG15C, YG18C, YG20C, YL60, YG22C, YG25C Ukusuka kwesobunxele kuya kwesokudla, ubunzima buyancipha, ukumelana nokuguguleka kuyancipha, futhi ukuqina kuyanda; ngokuphambene nalokho, okuphambene nalokho kuyiqiniso.

(3) Amathuluzi okulinganisa nezingxenye ezingagugi

I-Carbide isetshenziselwa ukufakwa kobuso obungagugi kanye nezingxenye zamathuluzi okulinganisa, ama-bearings anembile ama-grinder, amapuleti okuqondisa kanye nezinduku zokuqondisa zama-grinder angenasisekelo, iziqongo zama-lathe kanye nezinye izingxenye ezingagugi.

Izinsimbi ze-binder ngokuvamile ziyizinsimbi zeqembu lensimbi, ngokuvamile i-cobalt ne-nickel.

Lapho kukhiqizwa i-carbide esimende, usayizi wezinhlayiya zempuphu yezinto eziluhlaza ezikhethiwe uphakathi kwama-micron angu-1 no-2, futhi ubumsulwa buphezulu kakhulu. Izinto zokusetshenziswa zihlanganiswa ngokwesilinganiso sokwakheka esinqunyiwe, bese kuthi utshwala noma ezinye izinto ezisetshenziswayo zengezwe ekugayweni okumanzi kumshini wokugaya omanzi ukuze zixutshwe ngokuphelele futhi zigaywe. Hlunga ingxube. Ngemuva kwalokho, ingxube iyagoqwa, icindezelwe, bese ishiswa ekushiseni okuseduze nendawo yokuncibilika kwensimbi yesibambeli (1300-1500 °C), isigaba esiqinile kanye nensimbi yesibambeli kuzokwakha i-alloy eutectic. Ngemva kokupholisa, izigaba eziqinile zisatshalaliswa kugridi eyakhiwe ngensimbi esibambeli futhi zixhunywe eduze komunye nomunye ukuze zakhe into eqinile. Ubulukhuni be-carbide esimende buxhomeke kokuqukethwe kwesigaba esiqinile kanye nosayizi wezinhlamvu, okungukuthi, lapho okuqukethwe kwesigaba esiqinile kuphakeme futhi izinhlamvu zincane, kuba bukhulu ubulukhuni. Ukuqina kwe-carbide esimende kunqunywa yinsimbi yesibambeli. Uma okuqukethwe kwensimbi yesibambeli kuphakeme, kulapho amandla okuguquguquka aphezulu khona.

Ngo-1923, uSchlerter waseJalimane wanezela i-cobalt engu-10% kuya ku-20% ku-tungsten carbide powder njenge-binder, wasungula i-alloy entsha ye-tungsten carbide ne-cobalt. Ubulukhuni bulandela idayimane kuphela. I-carbide yokuqala eyenziwe nge-cemented. Lapho kusikwa insimbi ngethuluzi elenziwe ngaleli ngxube, unqenqema olusika luzoguga ngokushesha, futhi ngisho nonqenqema olusika luzoqhekeka. Ngo-1929, uSchwarzkov e-United States wanezela inani elithile le-tungsten carbide kanye ne-titanium carbide compound carbides ekwakhiweni kokuqala, okwathuthukisa ukusebenza kwethuluzi ekusikeni insimbi. Lokhu kungenye impumelelo emlandweni wokuthuthukiswa kwe-carbide eyenziwe nge-cemented.

I-carbide efakwe usimende inezimpawu ezinhle kakhulu njengokuqina okuphezulu, ukumelana nokuguguleka, amandla nokuqina okuhle, ukumelana nokushisa kanye nokumelana nokugqwala, ikakhulukazi ubulukhuni bayo obukhulu kanye nokumelana nokuguguleka, okungashintshi ngisho noma izinga lokushisa lingu-500 °C, isenobulukhuni obukhulu ku-1000℃. I-Carbide isetshenziswa kabanzi njengezinto zamathuluzi, njengamathuluzi okujika, okusika izigayo, ama-planer, ama-drill, amathuluzi okubhoboza, njll., ukusika insimbi ephothiwe, izinsimbi ezingezona i-ferrous, amapulasitiki, imicu yamakhemikhali, i-graphite, ingilazi, itshe kanye nensimbi evamile, futhi ingasetshenziswa futhi ekusikeni izinto ezinzima ukushiswa njengomshini njengensimbi engashisi, insimbi engagqwali, insimbi ephezulu ye-manganese, insimbi yamathuluzi, njll. Ijubane lokusika lamathuluzi amasha e-carbide manje seliphindwe kangamakhulu kunensimbi yekhabhoni.

I-Carbide ingasetshenziswa futhi ukwenza amathuluzi okubhoboza amatshe, amathuluzi okumba, amathuluzi okubhoboza, amathuluzi okulinganisa, izingxenye ezingagugi, izinto zokubhula zensimbi, ama-cylinder liners, ama-precision bearings, ama-nozzles, ama-mold ensimbi (njenge-wire drawing dies, ama-bolt dies, ama-nut dies, kanye nama-fastener mold ahlukahlukene, ukusebenza okuhle kakhulu kwe-carbide eqinisiwe kancane kancane kwathatha indawo yama-mold ensimbi angaphambilini).

Kamuva, kwaphuma i-carbide eboshwe ngesamente. Ngo-1969, iSweden yathuthukisa ngempumelelo ithuluzi eliboshwe nge-titanium carbide. Isisekelo saleli thuluzi yi-tungsten-titanium-cobalt carbide noma i-tungsten-cobalt carbide. Ubukhulu be-titanium carbide coating ebusweni bungama-microns ambalwa kuphela, kodwa uma kuqhathaniswa nohlobo olufanayo lwamathuluzi e-alloy, Impilo yesevisi yandiswa izikhathi ezi-3, futhi ijubane lokusika landa ngo-25% kuya ku-50%. Ngawo-1970, kwavela isizukulwane sesine samathuluzi aboshwe okusika izinto ezilukhuni ukuzisebenzisela umshini.

I-carbide efakwe i-cement ihlanzwa kanjani?

I-carbide esimende iyinto yensimbi eyenziwe nge-powder metallurgy yama-carbide kanye ne-binder metals yensimbi eyodwa noma ngaphezulu ephikisayo.

Mamazwe akhiqizayo

Kunamazwe angaphezu kwama-50 emhlabeni akhiqiza i-carbide esimende, enomkhiqizo ophelele ongama-27,000-28,000t-. Abakhiqizi abakhulu yi-United States, iRussia, iSweden, iShayina, iJalimane, iJapan, i-United Kingdom, iFrance, njll. Imakethe ye-carbide esimende yomhlaba wonke igcwele kakhulu. , umncintiswano wemakethe unamandla kakhulu. Imboni ye-carbide esimende yaseShayina yaqala ukubonakala ngasekupheleni kwawo-1950. Kusukela ngawo-1960 kuya kuma-1970, imboni ye-carbide esimende yaseShayina yathuthuka ngokushesha. Ekuqaleni kwawo-1990, umthamo wokukhiqiza ophelele we-carbide esimende yaseShayina wafinyelela kuma-6000t, kanti umkhiqizo ophelele we-carbide esimende wafinyelela kuma-5000t, owesibili kuphela eRussia nase-United States, ubekwe endaweni yesithathu emhlabeni.

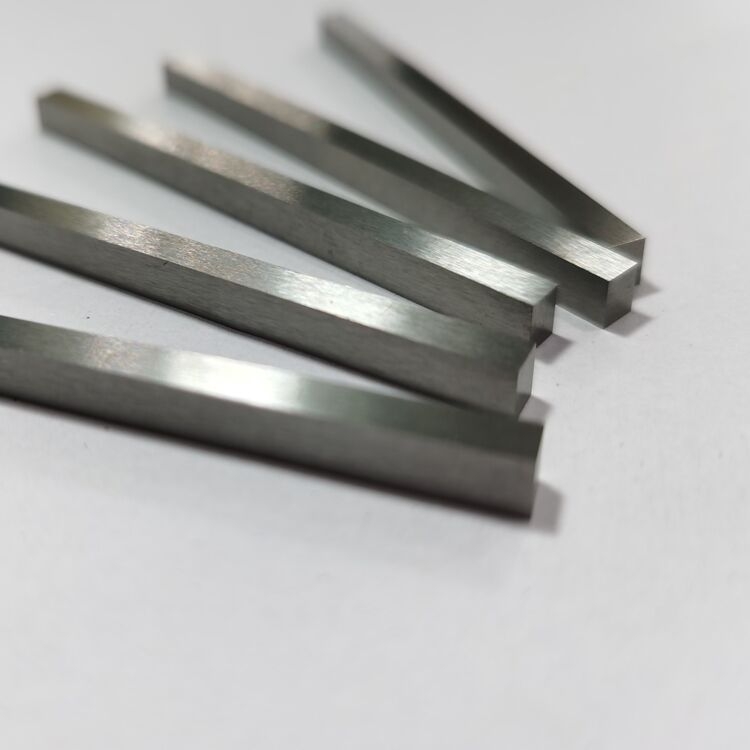

Umsiki we-WC

①I-tungsten ne-cobalt cemented carbide

Izingxenye eziyinhloko yi-tungsten carbide (WC) kanye ne-binder cobalt (Co).

Izinga layo lakhiwe yi-“YG” (“i-hard and cobalt” ngesi-Chinese Pinyin) kanye nephesenti lokuqukethwe kwe-cobalt okumaphakathi.

Isibonelo, i-YG8 isho isilinganiso se-WCo=8%, kanti okunye kuyi-tungsten-cobalt carbide ye-tungsten carbide.

Imimese ye-TIC

②I-Tungsten-titanium-cobalt carbide

Izingxenye eziyinhloko yi-tungsten carbide, i-titanium carbide (TiC) kanye ne-cobalt.

Uhlobo lwayo lwakhiwe yizinhlamvu ezimbili ezithi “YT” (“hard, titanium” ngesibongo sesiShayina sePinyin) kanye nokuqukethwe okumaphakathi kwe-titanium carbide.

Isibonelo, i-YT15 isho i-WTi evamile = 15%, kanti okunye kuyi-tungsten carbide kanye ne-tungsten-titanium-cobalt carbide enokuqukethwe kwe-cobalt.

Ithuluzi le-Tungsten Titanium Tantalum

③I-carbide eqiniswe nge-Tungsten-titanium-tantalum (niobium)

Izingxenye eziyinhloko yi-tungsten carbide, i-titanium carbide, i-tantalum carbide (noma i-niobium carbide) kanye ne-cobalt. Lolu hlobo lwe-carbide olufakwe i-cemented lubizwa nangokuthi i-general cemented carbide noma i-universal cemented carbide.

Ibanga layo lakhiwe ngo-“YW” (isiqalo sefonetiki yesiShayina esithi “hard” kanye no-“wan”) kanye nenombolo yokulandelana, njenge-YW1.

Izici zokusebenza

Ukufakwa Okuhlanganisiwe Kwe-Carbide

Ubulukhuni obuphezulu (86 ~93HRA, okulingana no-69 ~81HRC);

Ubulukhuni obuhle bokushisa (kufika ku-900 ~1000 ℃, gcina i-60HRC);

Ukumelana okuhle nokuklwebheka.

Amathuluzi okusika ama-carbide ashesha ngokuphindwe ka-4 kuya ku-7 kunensimbi enesivinini esikhulu, futhi impilo yamathuluzi iphakeme ngokuphindwe ka-5 kuya ku-80. Uma kwakhiwa isikhunta namathuluzi okulinganisa, impilo yesevisi iphakeme ngokuphindwe ka-20 kuya ku-150 kunensimbi yensimbi ye-alloy. Ingasika izinto eziqinile ezingaba ngu-50HRC.

Kodwa-ke, i-carbide esimende iyaphuka futhi ayikwazi ukushintshwa ngomshini, futhi kunzima ukwenza amathuluzi ahlanganisiwe anezimo eziyinkimbinkimbi. Ngakho-ke, kuvame ukwenziwa ama-blade ezimo ezahlukene, afakwa emzimbeni wamathuluzi noma emzimbeni wesikhunta ngokushisela, ukubopha, ukubopha ngomshini, njll.

Ibha enomumo okhethekile

Ukuhlanza

Ukubumba i-carbide esisamente kuwukucindezela i-powder ibe yi-billet, bese ungena esithandweni sokufudumeza ukuze sishise kufike ezingeni lokushisa elithile (izinga lokushisa elishisayo), usigcine isikhathi esithile (isikhathi sokubamba), bese usipholisa ukuze uthole izinto ze-carbide esisamente ezinezakhiwo ezidingekayo.

Inqubo yokusila i-carbide esimende ingahlukaniswa ngezigaba ezine eziyisisekelo:

1: Esigabeni sokususa i-ejenti yokwakha kanye nokuhlikihla ngaphambi kokuhlikihla, umzimba ohlikihliwe uyashintsha kanje:

Ukususwa kwe-ejenti yokubumba, ngokukhuphuka kwezinga lokushisa esigabeni sokuqala sokubumba, i-ejenti yokubumba iyabola kancane kancane noma iphele, bese umzimba omboziwe ukhishwa. Uhlobo, ubuningi kanye nenqubo yokubumba kuhlukile.

Ama-oxide ebusweni bempuphu ayancishiswa. Lapho izinga lokushisa lincishiswa, i-hydrogen inganciphisa ama-oxide e-cobalt ne-tungsten. Uma into edala isuswa ku-vacuum bese incishiswa, ukusabela kwe-carbon-oxygen akunamandla. Ukucindezeleka kokuxhumana phakathi kwezinhlayiya zempuphu kuyasuswa kancane kancane, i-bonding metal powder iqala ukululama futhi iphinde isetshenziswe, ukusabalala kobuso kuqala ukwenzeka, futhi amandla e-briquetting ayathuthuka.

2: Isigaba sokushiswa kwesigaba esiqinile (800℃–eutectic temperature)

Emazingeni okushisa ngaphambi kokuvela kwesigaba soketshezi, ngaphezu kokuqhubeka nenqubo yesigaba sangaphambilini, ukusabela kwesigaba esiqinile kanye nokusabalala kuyaqiniswa, ukugeleza kwepulasitiki kuyakhuliswa, futhi umzimba osikiwe uncipha kakhulu.

3: Isigaba sokusila sesigaba soketshezi (izinga lokushisa le-eutectic - izinga lokushisa lokusila)

Uma isigaba soketshezi sivela emzimbeni osikiwe, ukuncishiswa kuqedwa ngokushesha, kulandelwe ukuguqulwa kwekristalografikhi ukuze kwakheke isakhiwo esiyisisekelo kanye nesakhiwo se-alloy.

4: Isigaba sokupholisa (izinga lokushisa lokushisa - izinga lokushisa legumbi)

Kulesi sigaba, isakhiwo kanye nokwakheka kwesigaba se-alloy kunezinguquko ezithile ezihambisana nezimo zokupholisa ezahlukene. Lesi sici singasetshenziswa ukushisa i-carbide eqinisiwe ukuze kuthuthukiswe izakhiwo zayo zomzimba nezemishini.

Isikhathi sokuthunyelwe: Ephreli-11-2022