Ukumelana okungavamile kokugugulekaama-blade e-tungsten carbide, yize ingcono kunezinye izinto eziningi zokusika, noma kunjalo ingase yonakale kancane kancane ngezindlela eziningi ngasikhathi sinye lapho isebenza ngokuqhubekayo isikhathi eside. Ukuqonda lezi zinqubo zokuguguleka kubalulekile ekuthuthukiseni izindlela zokulwa ezisebenzayo kanye nokwenza ngcono ukusebenza kwe-blade ezisetshenziswayo ezimbonini.

1. Ukugqoka Okungagugi

Ukuguguleka okugugulekayo kungenye yezindlela zokugqoka ezivame kakhulu nezibaluleke kakhulu kwezomnotho ezithintaama-blade e-tungsten carbideekusebenzeni okuqhubekayo. Le nqubo yenzeka lapho ukufakwa okuqinile noma izinhlayiya eziqiniswe umsebenzi ezintweni zokusebenza zihlangana ngomshini nobuso be-blade, okuholela ekususweni kwezinto kancane kancane ngezenzo zokusika nokulima okuncane. Ubulukhuni obukhulu beokusanhlamvu kwe-tungsten carbideinikeza ukumelana okukhulu nale ndlela yokuguguleka, kodwa isigaba se-cobalt binder esithambile sisengozini enkulu yokuguguleka, okungenzeka kuholele ekuphumeni kwezinhlayiya ze-WC kanye nokuqhekeka kwazo okulandelayo noma ukukhishwa kwazo. Ucwaningo lubonisa ukuthi ukuguguleka okugugulekayo kuvame kakhulu lapho kusetshenziswa izinto zomshini eziqukethe izinto ezigugulekayo njenge-silicon-aluminium alloys, izinto ezihlanganisiwe, noma izinto zokusebenza ezinezikali zobuso eziqinile.

Izinga lokuguguleka okuhudulayo lithonywa izici eziningana, okuhlanganisa usayizi kanye nesimo sezinhlayiya ezihudulayo, izakhiwo zemishini zento yokusebenza kanye nezinto ze-blade, kanye nezimo zokusika ezisetshenziswayo. Ukubonwa kwezimboni kuqinisekisa ukuthi ukuguguleka okuhudulayo kuvame ukubonakala njengokuguguleka okufanayo kobuso becala lethuluzi noma ukwakheka kwemifantu ebusweni bokuxhumana kwe-chip, kanti izinga lokuguguleka ngokuvamile lihlobene ngqo nebanga lokusika futhi ngokuphambene nobunzima bokusika.

2. Ukugqoka Okubanzi

Ukuguguleka kokusabalalisa, okwaziwa nangokuthi ukuguguleka kokusabalalisa, kuba yinto ebaluleke kakhulu ekusetshenzisweni komshini wokushisa okuphezulu lapho amazinga okushisa okusika edlula khona ama-800°C. Kula mazinga okushisa aphezulu, izakhi zamakhemikhali ze-tungsten carbide blade kanye nezinto zokusebenza ziya ngokuya zihamba, okuholela ekusakazweni okufanayo kuyo yonke indawo yokusebenzisa ithuluzi nomsebenzi. Lesi simo sibonakala kakhulu lapho kusetshenziswa izinto ze-ferrous, lapho insimbi evela emsebenzini ingasakazeka khona iye ebheleni le-carbide kuyilapho i-carbon, i-tungsten, ne-cobalt evela ebheleni isakazeka iye ezintweni ze-chip.

Inqubo yokusabalala ishintsha ngokuyisisekelo ukwakheka kanye nezakhiwo zezingqimba zobuso be-blade. Njengoba ama-athomu e-carbon ehamba esuka ebusweni be-blade, amakristalu e-WC ayawohloka, okuholela ekunciphiseni ubulukhuni kanye nobuqotho bomshini. Ngesikhathi esifanayo, ukusabalala kwe-cobalt kwenza buthaka ukubopha phakathi kwezinhlayiya ze-tungsten carbide, okwenza kube nzima kakhulu ukuqina kwe-blade. Lokhu konakala kwamakhemikhali kuvame ukuholela ekwakhekeni kokuguguleka kwe-crater ebusweni be-rake yethuluzi, lapho ukujula okuphezulu kokuguguleka kwenzeka endaweni yokushisa okuphezulu kakhulu. Izifundo zibonise ukuthi ukufaka i-titanium carbide (TiC) ekwakhiweni kwe-tungsten carbide kunganciphisa kakhulu ukuguguleka kokusabalala ngenxa ye-TiC's diffusion coefficient ephansi uma iqhathaniswa ne-WC kanye nekhono layo lokwakha izingqimba ze-titanium oxide ezivikelayo emazingeni okushisa aphezulu.

3. Ukugqokwa Okunamathelayo Nokwekhemikhali

Ukuguguleka kokunamathela kwenzeka lapho izingcezu ezincane zezinto zokusebenza zihlanganiswa ebusweni be-blade ngaphansi kwethonya elihlangene lokucindezela okuphezulu kanye nokushisa esibonakalayo sethuluzi-i-workpiece. Lezi zinhlanganisela zokunamathela zingaphuka kamuva ngesikhathi sokunyakaza okuhlobene, okuholela ekususweni kwezinhlayiya ezincane ebusweni be-blade. Le ndlela ivame kakhulu lapho kulungiswa izinto ezithambile ezivame ukunamathela kuzo.amathuluzi okusika, njenge-aluminium alloys noma izinsimbi ezithile ezingagqwali.

Ngesikhathi esifanayo, izinqubo zokuguguleka kwamakhemikhali, okuhlanganisa i-oxidation kanye nezinye izindlela zokusabela kwe-thermochemical, zingasiza kakhulu ekuwohlokeni kwama-blade, ikakhulukazi ezindaweni ezishisa kakhulu.I-Tungsten carbideingaxuba ukuze yakhe i-tungsten oxide kanye ne-carbon dioxide emazingeni okushisa angaphezu kuka-600°C, kuyilapho izinto zokubopha i-cobalt nazo zisengozini yokuxuba, okungase kuholele ekuqhekekeni kwesigaba sokubopha se-blade kanye nokulahlekelwa okubangelwa yizinhlamvu ze-tungsten carbide. Ukuba khona kwezinto ezithile zamakhemikhali ezintweni zokusebenza, njenge-chlorine noma i-sulfur kwezinye izinhlobo, kungasheshisa lezi zinqubo zokuguguleka kwamakhemikhali ngokwakhiwa kwemikhiqizo yokusabela eguquguqukayo noma enamandla aphansi.

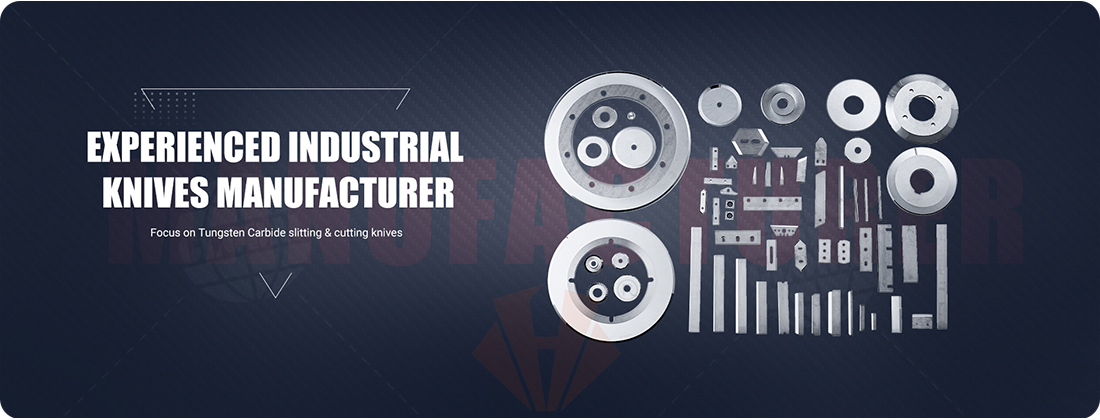

Mayelana neHuaxin: Umkhiqizi Wemimese Yokusika Ene-Cemented Tungsten Carbide

I-CHENGDU HUAXIN CEMENTED CARBIDE CO., LTD ingumhlinzeki ochwepheshe kanye nomkhiqizi wemikhiqizo ye-tungsten carbide, njengemimese yokufaka i-carbide yokwenza ukhuni, imimese eyindilinga ye-carbide yokusika izinduku zokuhlunga ugwayi nogwayi, imimese eyindilinga yokusika amakhadibhodi anezimbobo ezintathu, ama-razor blades/ama-slotted blades okupakisha, i-tape, ukusika ifilimu encane, ama-fiber cutter blades embonini yezindwangu njll.

Njengoba sekuyiminyaka engaphezu kwengu-25 sithuthukisa imikhiqizo yethu, ithunyelwe kwamanye amazwe e-US A, Russia, South America, India, Turkey, Pakistan, Australia, Southeast Asia njll. Ngekhwalithi enhle kakhulu namanani ancintisanayo, isimo sethu sengqondo sokusebenza kanzima kanye nokuphendula kuyavunyelwa amakhasimende ethu. Futhi singathanda ukwakha ubudlelwano obusha bebhizinisi namakhasimende amasha.

Xhumana nathi namuhla futhi uzojabulela izinzuzo zekhwalithi enhle kanye nezinsizakalo ezivela emikhiqizweni yethu!

Imikhiqizo yezimboni ze-tungsten carbide esebenza kahle kakhulu

Isevisi Yangokwezifiso

I-Huaxin Cemented Carbide ikhiqiza ama-blade e-tungsten carbide enziwe ngokwezifiso, ama-blank ashintshiwe ajwayelekile najwayelekile kanye nama-preform, kusukela ku-powder kuya kuma-blank aqediwe. Ukukhetha kwethu okuphelele kwama-grade kanye nenqubo yethu yokukhiqiza kunikeza njalo amathuluzi asebenza kahle kakhulu, athembekile acishe abe yi-net abhekana nezinselele ezikhethekile zokusetshenziswa kwamakhasimende kuzo zonke izimboni ezahlukahlukene.

Izixazululo Ezilungiselelwe Yonke Imboni

ama-blade aklanywe ngokwezifiso

Umkhiqizi ohamba phambili wama-blade ezimboni

Imibuzo evamile yamakhasimende kanye nezimpendulo ze-Huaxin

Lokho kuncike enanini, ngokuvamile izinsuku ezi-5-14. Njengomkhiqizi wezinsika zezimboni, i-Huaxin Cement Carbide ihlela ukukhiqizwa ngama-oda kanye nezicelo zamakhasimende.

Ngokuvamile amasonto ama-3-6, uma ucela imimese yomshini eyenziwe ngokwezifiso noma ama-blade ezimboni angekho esitokweni ngesikhathi sokuthenga. Thola i-Sollex Purchase & Delivery Conditions lapha.

uma ucela imimese yomshini eyenziwe ngokwezifiso noma ama-blade ezimboni angekho esitokweni ngesikhathi sokuthenga. Thola Izimo Zokuthenga Nokulethwa ze-Sollexlapha.

Ngokuvamile i-T/T, i-Western Union...idiphozithi kuqala, Wonke ama-oda okuqala avela kumakhasimende amasha akhokhelwa kusengaphambili. Ama-oda engeziwe angakhokhwa nge-invoyisi...Xhumana nathiukwazi okwengeziwe

Yebo, xhumana nathi, imimese yezimboni iyatholakala ngezindlela ezahlukene, kufaka phakathi imimese enesitsha esiphezulu, imimese eyindilinga engezansi, imimese enezinyo ezigobile/ezinamazinyo, imimese ebhoboza nxazonke, imimese eqondile, imimese ye-guillotine, imimese ecijile, imimese ye-razor engunxande, kanye nemimese ye-trapezoidal.

Ukuze sikusize uthole i-blade engcono kakhulu, i-Huaxin Cement Carbide ingakunikeza ama-blade amaningana amasampula ongawahlola ekukhiqizweni. Ukuze usike futhi uguqule izinto eziguquguqukayo njengefilimu yepulasitiki, i-foil, i-vinyl, iphepha, nokunye, sinikeza ama-blade okuguqula kufaka phakathi ama-slitter blade anezikhala kanye nama-razor blade anezikhala ezintathu. Sithumelele umbuzo uma unentshisekelo kuma-blade omshini, futhi sizokunikeza isipho. Amasampula emimese eyenziwe ngokwezifiso awatholakali kodwa wamukelekile uku-oda inani elincane kakhulu le-oda.

Kunezindlela eziningi ezizokwandisa isikhathi eside kanye nokuphila kweshelufu kwemimese yakho yezimboni kanye nama-blade esitokweni. Xhumana nathi ukuze wazi ukuthi ukupakishwa okufanele kwemimese yomshini, izimo zokugcina, umswakama kanye nokushisa komoya, kanye nokwembozwa okwengeziwe kuzovikela imimese yakho futhi kugcine ukusebenza kwayo kokusika.

Isikhathi sokuthunyelwe: Okthoba-24-2025