Izinto ezijwayelekile zamathuluzi e-carbide aqinisiwe zihlanganisa kakhulu i-carbide eqinisiwe esekelwe ku-tungsten carbide, i-carbide eqinisiwe esekelwe ku-TiC(N), i-carbide eqinisiwe ene-TaC (NbC eyengeziwe), kanye ne-carbide eqinisiwe kakhulu. Ukusebenza kwezinto ze-carbide eziqinisiwe kunqunywa kakhulu yizigaba zokuqinisa ezengeziwe.

I-Carbide Eqinisiwe Ene-TaC Eyengeziwe (i-NbC)

Ukwengeza i-TaC (NbC) ku-carbide eqinisiwe kuyindlela ephumelelayo yokuthuthukisa ukusebenza kwayo. Kuma-alloy e-TiC/Ni/Mo, ukufaka esikhundleni ingxenye ye-TiC ngama-carbide afana ne-WC ne-TaC, anikeza ukuqina okungcono, kuthuthukisa ukusebenza kwe-carbide eqinisiwe futhi kwandise ububanzi bokusetshenziswa kwayo. Ukwengezwa kwe-WC ne-TaC kuthuthukisa:

● Ukuqina

● I-modulus enwebekayo

● Ukumelana nokuguqulwa kwepulasitiki

● Amandla okushisa aphezulu

Futhi kuthuthukisa ukuhanjiswa kokushisa kanye nokumelana nokushaqeka kokushisa, okwenza ithuluzi lifaneleke kakhulu ekusikeni okuphazamisekile. Kuma-alloy e-WC-Co, ukusebenza kungathuthukiswa ngokungeza u-0.5% kuya ku-3% (ingxenye yesisindo) sama-carbide njenge-TaC, i-NbC, i-Cr3C2, i-VC, i-TiC, noma i-HfC. Izinhloso eziyinhloko zifaka:

● Ukuhluzwa kokusanhlamvu

● Ukugcina isakhiwo sekristalu esifanayo ngaphandle kokuphinda kusetshenziswe kabusha

● Ukwandisa ubulukhuni nokumelana nokuguguleka ngaphandle kokubeka engcupheni ukuqina

Ngaphezu kwalokho, lezi zithasiselo ziyasiza:

● Ubulukhuni obuphezulu bokushisa

● Amandla okushisa aphezulu

● Ukumelana ne-oxidation

Ngesikhathi sokusika, kwakheka ifilimu ye-oxide eqinile, ezikhokhelayo, emelana nokuguguleka okunamathelayo kanye nokusabalala lapho kulungiswa izinsimbi noma ama-alloy athile. Lokhu kuthuthukisa ukumelana nokuguguleka kwethuluzi futhi kwandisa ikhono lalo lokumelana nokuguguleka kwe-crater kanye nokuguguleka kwe-flank. Lezi zinzuzo ziba sobala kakhulu njengoba okuqukethwe yi-cobalt ku-carbide eqinisiwe kukhuphuka.

● I-carbide efakwe usimende ene-1% kuya ku-3% (ingxenye yesisindo) i-TaC (NbC) ingasebenzisa izinsimbi ezahlukahlukene ezihlanganisiwe, okuhlanganisa insimbi eqinile kakhulu kanye nensimbi ehlanganisiwe.

● Ama-alloy e-cobalt aphansi ane-3% kuya ku-10% (ingxenye enkulu) i-TaC (NbC), njenge-YG6A, YG8N, kanye ne-YG813, ayasebenziseka ngezindlela eziningi. Angacubungula:

Insimbi ephothiwe ebandayo

Insimbi ephonswe nge-ductile

Izinsimbi ezingezona i-ferrous

Izinto ezilukhuni ukushintshwa njengomshini wensimbi engagqwali, insimbi eqinile, kanye nezinsimbi ezisebenza ngokushisa okuphezulu

Lezi zaziwa kakhulu ngokuthi ama-alloy ajwayelekile (YW). Ukwandisa okuqukethwe kwe-cobalt kukhulisa amandla nokuqina kwalolu hlobo lwe-carbide oluqinisiwe, okwenza lufanelekele ukwenziwa ngomshini onzima kanye nokusikwa okuphazamisekile kwezinto ezilukhuni ukukwenziwa emshinini. Izicelo zifaka:

● Ukuhlikihla izinsimbi ezinkulu ezibunjiweyo nezingcwecwe

● Ukujika, ukuphotha, nokugaya insimbi ye-austenitic kanye ne-alloys engashisi

● Umshini wokusika ngama-engeli amakhulu erekhi, izingxenye ezinkulu zokusika, kanye nesivinini esiphakathi kuya kwesiphansi

● Ukuvula ngokungemthetho ama-lathe azenzakalelayo, azenzakalelayo, kanye namathuluzi amaningi

● Ukukhiqiza imishini yokubhoboza, ama-gear hobs, namanye amathuluzi anamandla aphezulu okusebenza**

Kuma-alloy e-WC-TiC-Co, okuqukethwe kwe-TiC ngokweqile kwandisa ukuzwela ekuqhekekeni kokushisa, okuholela ekuqhekekeni okukhulu. Ukwengeza i-TaC kuma-alloy e-WC-Ti-Co ane-cobalt ephansi, kuyathuthuka:

● Ukuqina

● Ukumelana nokushisa

● Ukumelana ne-oxidation

Nakuba i-TiC yehlisa ukumelana nokushaqeka kokushisa, i-TaC iyayikhokhela lokhu, okwenza i-alloy ifaneleke ukusebenza kokugaya. Ezinye izindlela ezingabizi kakhulu njenge-NbC noma i-Hf-Nb carbides (ingxenye enkulu: Hf-60%, Nb-40%) ingathatha indawo ye-TaC. Kuma-alloy e-TiC-Ni-Mo, ukwengeza i-TiN, i-WC, kanye ne-TaC ngesikhathi esisodwa kuthuthukisa kakhulu:

● Ukuqina

● Amandla okugobeka

● Ukumelana ne-oxidation

● Ukushisa okusebenzayo

emazingeni okushisa aphezulu (900–1000°C).

I-Carbide Ene-Cemented Ene-Ultrafine Grain

Ukucwenga izinhlamvu ze-carbide esimende kunciphisa usayizi wesigaba esiqinile, kwandisa indawo engaphezulu kwezinhlayiya zesigaba esiqinile kanye namandla okubopha phakathi kwezinhlayiya. Isigaba sokubopha sisabalala ngokulinganayo nxazonke zazo, sithuthukisa:

Ubulukhuni

Ukumelana nokugqoka

Ukwandisa okuqukethwe kwe-cobalt ngendlela efanele kukhulisa amandla okuguquguquka. I-carbide eyenziwe nge-cemented e-ultrafine, eyakhiwe yizinhlayiya ezincane kakhulu ze-WC ne-Co, ihlanganisa:

Ubulukhuni obukhulu be-carbide esimende

Amandla ensimbi eshesha kakhulu

Ukuqhathaniswa kosayizi wezinhlamvu:

I-carbide evamile eqinisiwe: 3–5 μm

I-carbide ejwayelekile efakwe ucezu oluhle: ~1.5 μm

Ama-alloy aqukethe i-submicron: 0.5–1 μm

I-carbide eqiniswe nge-ultrafine grained: Usayizi we-WC grain ongaphansi kuka-0.5 μm

Ukuhluzwa kokusanhlamvu kuyathuthuka:

Ubulukhuni

Ukumelana nokugqoka

Amandla okugobeka

Ukumelana nokuqhekeka

Ubulukhuni obuphezulu bokushisa

Uma kuqhathaniswa ne-carbide evamile ehlanganisiwe efanayo, i-carbide ehlanganisiwe eyenziwe ngosimende esezingeni eliphezulu inikeza:

Ukwanda kokuqina kwama-HRA angaphezu kwama-2

Ukwanda kwamandla okuguquguquka kwe-MPa okungu-600–800

Izakhiwo ezijwayelekile:

Okuqukethwe kwe-Cobalt: 9%–15%

Ubulukhuni: 90–93 HRA

Amandla okugobeka: 2000–3500 MPa

Amabanga akhiqizwa eShayina afaka phakathi i-YS2 (YG10H, YG10HT), i-YM051 (YH1), i-YM052 (YH2), i-YM053 (YH3), i-YD05 (YC09), i-YD10 (YG1101), i-B60, i-YG610, i-YG643, kanye ne-YD05. Ngenxa yokusanhlamvu kwayo okuhle kakhulu, i-carbide efakwe ucezu oluqinile ingagaywa ibe yimiphetho yokusika ebukhali kakhulu enobukhulu obuphansi bomphezulu, okwenza ibe yindawo efaneleke kakhulu kumathuluzi okunemba afana nalawa:

Ama-Broaches

AmaReamers

Ama-hob aqondile

Ihamba phambili ekushiseni ngobubanzi obuncane bokusika kanye nezinga lokuphakela. Ifanele futhi amathuluzi amancane afana nalawa:

Ukuziqeqesha okuncane

Izigayi ezincane zokugaya

Ama-broaches amancane

Ama-hob amancane

Uma ithatha indawo yamathuluzi ensimbi asheshayo, isikhathi sayo sokuphila siphindwe izikhathi eziyi-10-40, okungenzeka sidlule izikhathi eziyi-100. Amathuluzi e-carbide aqiniswe nge-ultrafine afanelekela kakhulu imishini:

Ama-alloy asezingeni eliphezulu asekelwe ensimbini kanye nasekelwe ku-nickel

Ama-alloy e-titanium

Izinsimbi ezingagqwali ezingamelani nokushisa

Izinto ezifuthwe, ezishisiwe, nezimboziwe (isb., izimpushana ze-alloy ezisekelwe ensimbini, ezisekelwe ku-nickel, ezisekelwe ku-cobalt, ezizikhukhumezayo ezizikhukhumezayo, uchungechunge lwe-cobalt-chromium-tungsten)

Izinsimbi ezinamandla kakhulu

Izinsimbi eziqinile

Izinto zokuqina okuphezulu njengezinsimbi ezicijile ze-chromium ephezulu kanye ne-nickel-cooled

Uma kusetshenziswa izinto ezilukhuni ukukhiqizwa emshinini, isikhathi sayo sokuphila siphindwe kathathu kuya kweshumi kunese-carbide evamile efakwe usimende.

Kungani Ukhethe iChengduhuaxin Carbide?

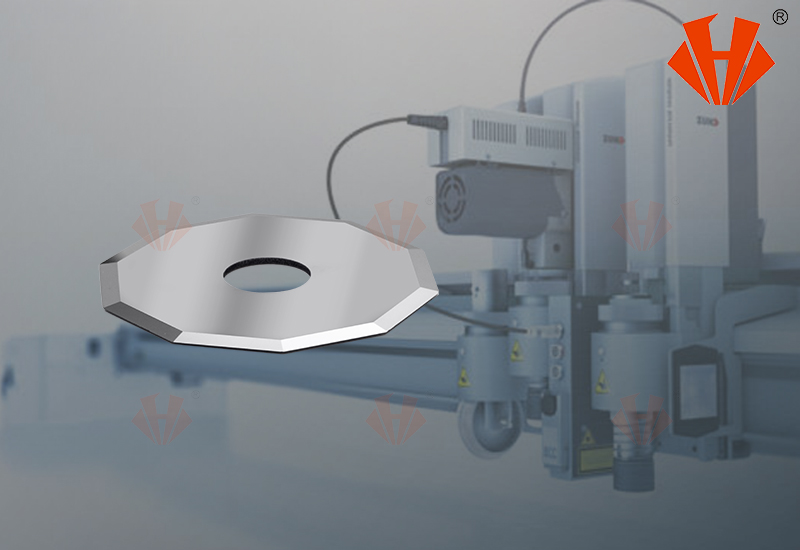

I-Chengduhuaxin Carbide ivelele emakethe ngenxa yokuzibophezela kwayo ekhwalithini nasekusunguleni izinto ezintsha. Ama-blade abo ekhaphethi e-tungsten carbide kanye nama-blade e-tungsten carbide aklanyelwe ukusebenza kahle kakhulu, anikeza abasebenzisi amathuluzi ahlinzeka ngokusika okuhlanzekile nokunembile ngenkathi ebekezelela ubunzima bokusetshenziswa kakhulu kwezimboni. Ngokugxila ekuqineni nasekusebenzeni kahle, ama-blade e-Chengduhuaxin Carbide anikeza ikhambi elifanele izimboni ezidinga amathuluzi okusika anokwethenjelwa.

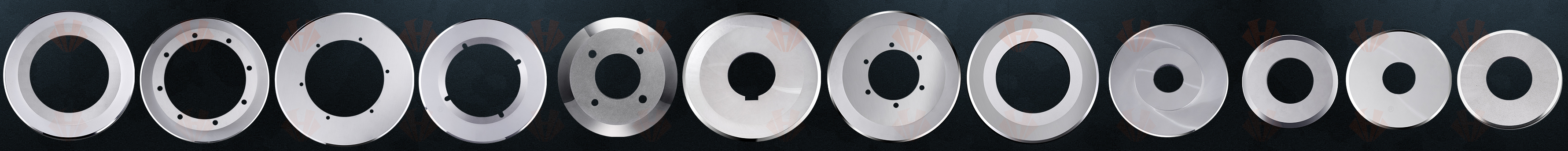

I-CHENGDU HUAXIN CEMENTED CARBIDE CO.,LTD ingumhlinzeki ochwepheshe kanye nomkhiqizi weimikhiqizo ye-tungsten carbide,njengemimese yokufaka i-carbide yokusebenza ngokhuni, i-carbideimimese eyindilingangobaizinduku zokuhlunga ugwayi nogwayi, imimese eyindilinga ukusika amakhadibhodi ane-corugat,ama-razor blades/ama-slotted blades anezimbobo ezintathu ukupakisha, iteyipu, ukusika ifilimu encane, ama-fiber cutter blades embonini yezindwangu njll.

Njengoba sekuyiminyaka engaphezu kwengu-25 sithuthukisa imikhiqizo yethu, ithunyelwe kwamanye amazwe e-US A, Russia, South America, India, Turkey, Pakistan, Australia, Southeast Asia njll. Ngekhwalithi enhle kakhulu namanani ancintisanayo, isimo sethu sengqondo sokusebenza kanzima kanye nokuphendula kuyavunyelwa amakhasimende ethu. Futhi singathanda ukwakha ubudlelwano obusha bebhizinisi namakhasimende amasha.

Xhumana nathi namuhla futhi uzojabulela izinzuzo zekhwalithi enhle kanye nezinsizakalo ezivela emikhiqizweni yethu!

Imibuzo evamile yamakhasimende kanye nezimpendulo ze-Huaxin

Lokho kuncike enanini, ngokuvamile izinsuku ezi-5-14. Njengomkhiqizi wezinsika zezimboni, i-Huaxin Cement Carbide ihlela ukukhiqizwa ngama-oda kanye nezicelo zamakhasimende.

Ngokuvamile amasonto ama-3-6, uma ucela imimese yomshini eyenziwe ngokwezifiso noma ama-blade ezimboni angekho esitokweni ngesikhathi sokuthenga. Thola i-Sollex Purchase & Delivery Conditions lapha.

uma ucela imimese yomshini eyenziwe ngokwezifiso noma ama-blade ezimboni angekho esitokweni ngesikhathi sokuthenga. Thola Izimo Zokuthenga Nokulethwa ze-Sollexlapha.

Ngokuvamile i-T/T, i-Western Union...idiphozithi kuqala, Wonke ama-oda okuqala avela kumakhasimende amasha akhokhelwa kusengaphambili. Ama-oda engeziwe angakhokhwa nge-invoyisi...Xhumana nathiukwazi okwengeziwe

Yebo, xhumana nathi, imimese yezimboni iyatholakala ngezindlela ezahlukene, kufaka phakathi imimese enesitsha esiphezulu, imimese eyindilinga engezansi, imimese enezinyo ezigobile/ezinamazinyo, imimese ebhoboza nxazonke, imimese eqondile, imimese ye-guillotine, imimese ecijile, imimese ye-razor engunxande, kanye nemimese ye-trapezoidal.

Ukuze sikusize uthole i-blade engcono kakhulu, i-Huaxin Cement Carbide ingakunikeza ama-blade amaningana amasampula ongawahlola ekukhiqizweni. Ukuze usike futhi uguqule izinto eziguquguqukayo njengefilimu yepulasitiki, i-foil, i-vinyl, iphepha, nokunye, sinikeza ama-blade okuguqula kufaka phakathi ama-slitter blade anezikhala kanye nama-razor blade anezikhala ezintathu. Sithumelele umbuzo uma unentshisekelo kuma-blade omshini, futhi sizokunikeza isipho. Amasampula emimese eyenziwe ngokwezifiso awatholakali kodwa wamukelekile uku-oda inani elincane kakhulu le-oda.

Kunezindlela eziningi ezizokwandisa isikhathi eside kanye nokuphila kweshelufu kwemimese yakho yezimboni kanye nama-blade esitokweni. Xhumana nathi ukuze wazi ukuthi ukupakishwa okufanele kwemimese yomshini, izimo zokugcina, umswakama kanye nokushisa komoya, kanye nokwembozwa okwengeziwe kuzovikela imimese yakho futhi kugcine ukusebenza kwayo kokusika.

Isikhathi sokuthunyelwe: Julayi-14-2025