Ukuqonda Imimese Yokushintsha Nezinzuzo Zayo Ezimbonini Ezihlukahlukene

Ziyini Imimese Yokuguqula Izinto?

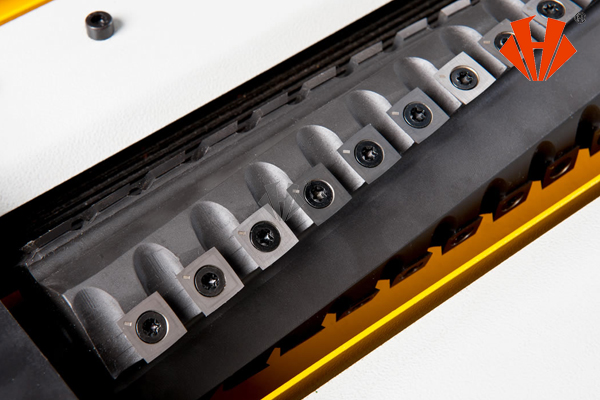

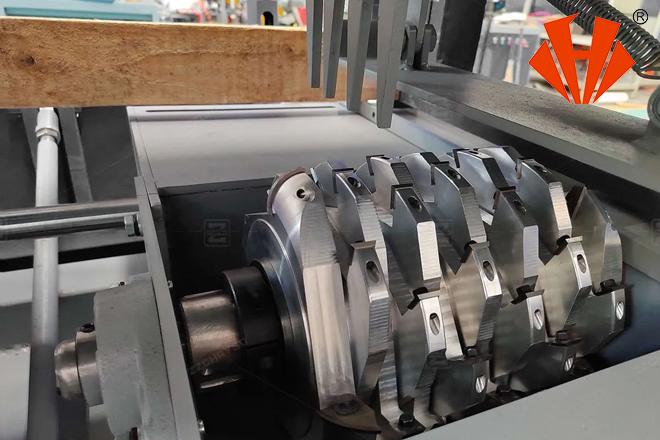

Imimese yokuguqula izinto ingamathuluzi okusika anemiphetho emibili, okuvumela ukuthi iguqulwe ukuze isetshenziswe isikhathi eside. Lokhu kusebenza okunemiphetho emibili kuyisici esibalulekile esithuthukisa isikhathi sokuphila nokusebenza kahle kwaleli thuluzi, kunciphisa isikhathi sokungasebenzi kanye nezindleko zokushintsha. Le mimese isetshenziswa kabanzi emishinini efana ne-grooving cutterheads, i-table shaper, kanye nemishini ye-edgeband, lapho ukusika ngokunemba kanye nokuphila isikhathi eside kubaluleke kakhulu.

Ama-Carbide Reversible Blades kanye Nezinzuzo Zawo

Ama-blade aguqulwayo e-carbide ayisinqumo esidumile semimese yokujika ngenxa yokusebenza kwawo okuhle kakhulu kanye nokusebenza kahle kwezindleko. Inzuzo eyinhloko yama-blade aguqulwayo ukuthi angaphendulwa uma uhlangothi olulodwa luguga, okwandisa kabili isikhathi sokusetshenziswa sommese. Enziwe nge-carbide esebenza kahle, lawa ma-blade amelana kakhulu nokuguga futhi angamelana nezicelo zokusika ngesivinini esikhulu. Lokhu kuwenza afaneleke kakhulu ezimbonini ezifana nokusebenza ngokhuni, lapho ukushintshwa kwamathuluzi njalo kungaholela ekungasebenzi kahle okukhulu.

Ukufakwa Kwe-Carbide Indexable kanye Nendima Yabo Emimeseni Yokuguquka

Izithako ze-carbide ezingafakwa uphawu ziyisici esivamile emimeseni yokujika, ikakhulukazi ekusebenzeni ngokhuni kanye nasekwenzeni insimbi. Lezi zithako zenzelwe ukushintshwa ngazinye uma sezibuthuntu, esikhundleni sokushintsha i-blade yonke. Inzuzo eyinhloko yezithako ze-carbide yikhono lazo lokugcina umkhawulo obukhali isikhathi eside, ngisho noma zisetshenziswa kakhulu. Ukushintshana kwezithako kuvumela izinguquko ze-blade ezisheshayo nezilula, okwenza ukulungiswa kube ngcono futhi kunciphise izindleko zokusebenza.

Ukusetshenziswa kwezifakelo ze-carbide eziqondakala kalula kuqinisekisa izinga eliphezulu lokunemba kokusika, njengoba izifakelo zakhiwe ngokunemba ukuze zilingane kahle nesiphathi sommese. Ngaphezu kwalokho, zitholakala ngejometri ehlukahlukene, okuvumela ukwenza ngokwezifiso kuye ngezidingo ezithile zokusika zohlelo lokusebenza.

Imimese Yokuguqula I-Carbide Eqinile

Ngezinhlelo zokusebenza ezidinga izinga eliphezulu lokuqina kanye nokunemba kokusika,imimese yokuguqula i-carbide eqinileNgokuvamile kuyisinqumo esikhethwayo. Le mimese yenziwe ngokuphelele ngezinto ze-carbide, inikeza ubulukhuni obuphezulu kanye nokumelana nokuguguleka uma kuqhathaniswa nemimese yensimbi evamile. Imimese yokuguqula i-carbide eqinile ivelele emisebenzini enembile njengokugaya, ukubumba, kanye nokusika, lapho umkhawulo obukhali nohambisanayo ubaluleke kakhulu.

Le mimese isebenza kahle kakhulu ezimbonini ezifana nokukhiqiza ifenisha, lapho kudingeka khona ukusika okuyinkimbinkimbi nokubucayi ezintweni ezifana nokhuni namabhodi afakwe i-laminate. Imimese eqinile ye-carbide ingabekezelela ukucindezeleka kwalokhu kusebenza ngaphandle kokufiphala ngokushesha, okuqinisekisa ukuthi ukukhiqizwa kuhlala kusebenza kahle.

Le mimese ivame ukwenziwa ngezinto eziqinile njengei-carbidenomainsimbi yesivinini esikhulu(HSS), kanti i-carbide ithandwa kakhulu ngenxa yokuqina kwayo kanye nokumelana nokuguguleka. Emsebenzini wokhuni, imimese yokujika isetshenziswa kuma-planer, ama-jointer, kanye nemishini yokugaya, lapho isiza khona ukugcina ukunemba nokusika okuhlanzekile ezinhlotsheni ezahlukene zokhuni. Ngaphezu kwalokho,imimese ephendukayo ye-carbidebaziswa kakhulu ngekhono labo lokuphatha izinkuni eziqinile ngaphandle kokubuthuntu ngokushesha njengemimese yensimbi yendabuko.

Imimese yokufaka i-carbide egqoke isikhathi eside engu-14.6x14.6x2.5mm iyatholakala emishinini ye-planer kanye ne-jointer ene-spiral helical cutterhead, umshini we-planer sander, i-groover, i-moulder cutterhead kanye nezinye izinhlelo zokusebenza zokhuni.

Sekukonke, imimese yokujika iyisisombululo esisebenzayo nesingabizi kakhulu ezimbonini ezidinga amathuluzi okusika anembile kakhulu nahlala isikhathi eside.

Imimese Yokuguqula I-Grooving kanye Nemimese Yokufaka I-Grooving Carbide

Enye yezindlela ezivame kakhulu zokusebenzisa imimese yokushintshana ikwi-grooving cutterheads.Imimese yokuguqula i-groovingzenzelwe ngqo ukusika imigoqo ibe yizinto zokwakha, okwenza zibe zilungele ukusetshenziswa njengokuhlanganisa, ukwenza amaphaneli, kanye nokusika izinkuni zokuhlobisa. Le mimese iyatholakala ngemiklamo ehlukahlukene, kufaka phakathiimimese yokufaka i-carbideezihlanganisa izinzuzo zokuqina kwe-carbide nokuguquguquka kwezinto ezifakwayo ezingashintshwa.

Imimese yokufaka i-carbide e-groovingzinikeza ukuguquguquka nokusebenza okuhlala isikhathi eside, njengoba zingashintshwa kalula ngezifakelo ezintsha uma sezigugile, ngaphandle kwesidingo sokushintsha ummese wonke. Lesi sici sizenza zibe yisisombululo esingabizi kakhulu sezimboni ezinezidingo zokukhiqiza eziningi.

Imimese Yokuguqula I-Tungsten Carbide Tipped (TCT)

Kwezinye izindawo zokunciphisa isidingo esikhulu,Imimese yokuguqula i-Tungsten Carbide Tipped (TCT)Kusetshenziswa imimese ye-TCT. Imimese ye-TCT ihlanganisa ukuqina kwensingo yensimbi nokumelana nokuguguleka kanye nobunzima be-tungsten carbide, okwenza ifaneleke ukusika izinto eziqinile njengezinkuni eziqinile kanye nezinhlanganisela.Imimese yokushintshana ye-TCTinikeza ukusebenza okuphezulu kokusika, ikakhulukazi ezinhlelweni ezifana nokubumba ukhuni, ukuqeda umphetho, kanye nokucubungula i-veneer.

Ukusetshenziswa kweImimese Yokuguqula I-Tungsten CarbideKulezi zinhlelo zokusebenza kuqinisekisa impilo yamathuluzi ende, okubaluleke kakhulu ezimbonini lapho ukukhiqiza nokusebenza kahle kubalulekile khona. Ngokunikeza izikhawu zesevisi ezinde phakathi kokushintsha kwamathuluzi, imimese yokushintshana ye-TCT inegalelo ekunciphiseni izindleko zokusebenza ngokuhamba kwesikhathi.

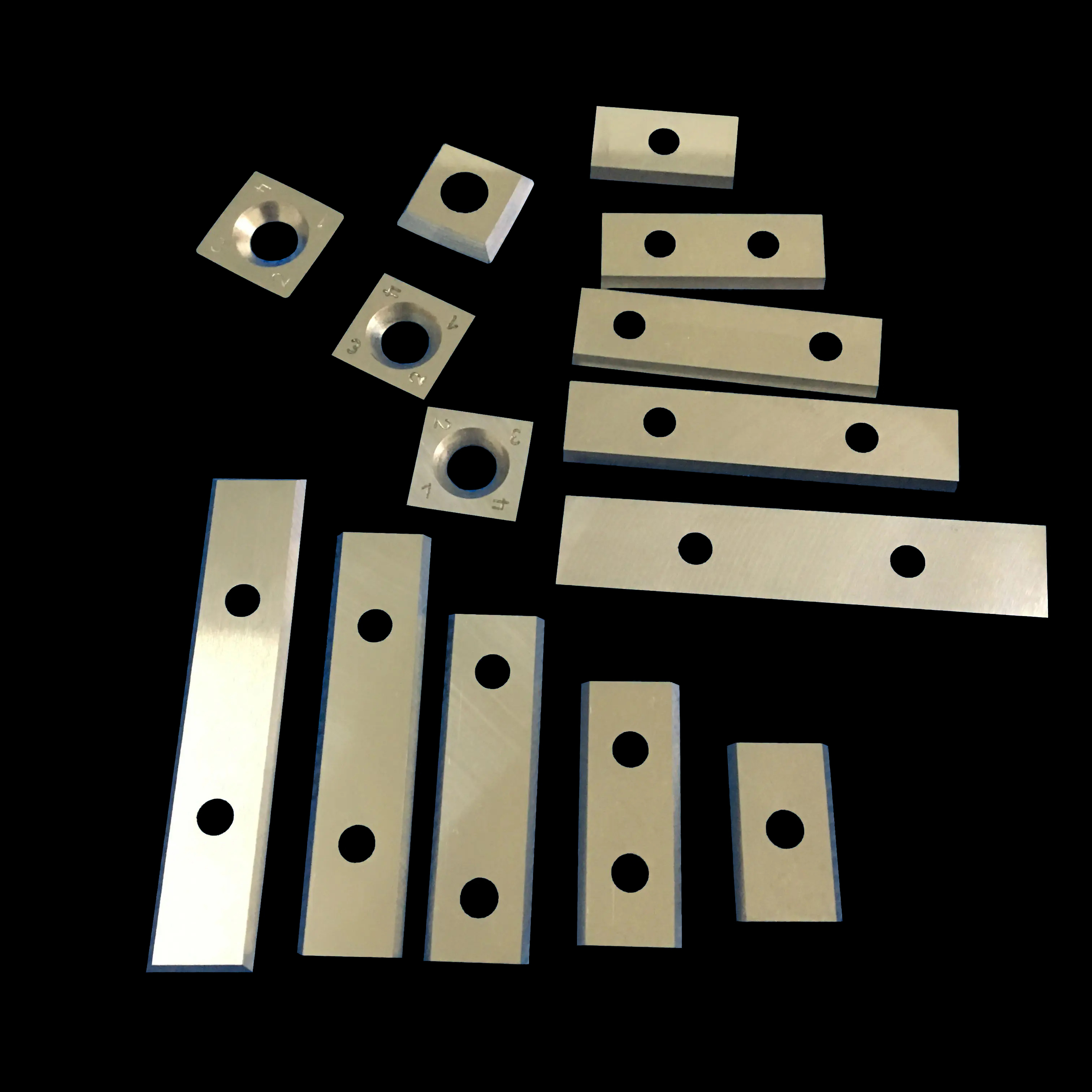

Imimese Yokuguqula I-Carbide Enemiphetho Emibili Nemiphetho Eminingi

Imimese ye-carbide enohlangothi oluphindwe kabilifuthiukufakwa kwe-carbide okunezinhlangothi eziningikungenye indlela entsha yokuklama imimese yokushintshashintsha. Le mimese inemiphetho eminingi yokusika, njengeImimese yokuguqula enezinhlangothi ezine or imimese yokuguqula i-radius, okuvumela impilo yamathuluzi nokusebenza kahle okukhulu nakakhulu. Lapho unqenqema olulodwa luba buthuntu, opharetha bangamane bajikelezise ummese ukuze basebenzise unqenqema olulandelayo olubukhali. Lo mklamo unciphisa kakhulu isikhathi sokungasebenzi futhi wandisa umkhiqizo jikelele.

Ngezinhlelo zokusebenza ezidinga amajiyometri okusika ayinkimbinkimbi,imimese yokuguqula i-radiusukunikeza ukunemba emisebenzini ehilela ukusika okugobile noma okugobile. Le mimese ingagcina ikhwalithi yokusika ehambisanayo futhi isize ukuqinisekisa ukushelela nokunemba komkhiqizo oqediwe.

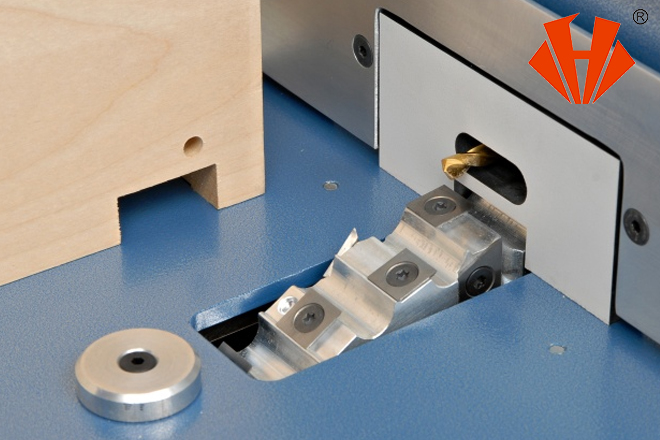

Imimese Yababumbi Betafula kanye Nokubopha Ama-Edgeband

Ngaphezu kokusetshenziswa kwazo ekugxumeni nasekubumbeni, imimese yokuguqula izinto nayo ibalulekile emishinini efanaababumbi betafulafuthiimishini yokufaka ibhande eliseceleni. Faka amathiphu e-carbide okusebenza ngokhuniziwusizo kakhulu kulezi zindawo, lapho imimese kumele ihlinzeke ngokusika okulinganayo nokubushelelezi ezingcezwini zokhuni nasemaphethelweni.Imimese yokufaka i-edgeband, ezisetshenziswa emishinini efaka imiphetho evikelayo efenisha noma emakhabetheni, zenzelwe ukuletha ukuqeda okungenaphutha ngenkathi kuqinisekiswa ukuthi imiphetho yokusika ihlala ibukhali phakathi nokugijima isikhathi eside.

Imimese Yokuguqula I-Carbide Enemiphetho Emibili Nemiphetho Eminingi

Imimese ye-carbide enohlangothi oluphindwe kabilifuthiukufakwa kwe-carbide okunezinhlangothi eziningikungenye indlela entsha yokuklama imimese yokushintshashintsha. Le mimese inemiphetho eminingi yokusika, njengeImimese yokuguqula enezinhlangothi ezine or imimese yokuguqula i-radius, okuvumela impilo yamathuluzi nokusebenza kahle okukhulu nakakhulu. Lapho unqenqema olulodwa luba buthuntu, opharetha bangamane bajikelezise ummese ukuze basebenzise unqenqema olulandelayo olubukhali. Lo mklamo unciphisa kakhulu isikhathi sokungasebenzi futhi wandisa umkhiqizo jikelele.

Ngezinhlelo zokusebenza ezidinga amajiyometri okusika ayinkimbinkimbi,imimese yokuguqula i-radiusukunikeza ukunemba emisebenzini ehilela ukusika okugobile noma okugobile. Le mimese ingagcina ikhwalithi yokusika ehambisanayo futhi isize ukuqinisekisa ukushelela nokunemba komkhiqizo oqediwe.

Imimese Yababumbi Betafula kanye Nokubopha Ama-Edgeband

Ngaphezu kokusetshenziswa kwazo ekugxumeni nasekubumbeni, imimese yokuguqula izinto nayo ibalulekile emishinini efanaababumbi betafulafuthiimishini yokufaka ibhande eliseceleni. Faka amathiphu e-carbide okusebenza ngokhuniziwusizo kakhulu kulezi zindawo, lapho imimese kumele ihlinzeke ngokusika okulinganayo nokubushelelezi ezingcezwini zokhuni nasemaphethelweni.Imimese yokufaka i-edgeband, ezisetshenziswa emishinini efaka imiphetho evikelayo efenisha noma emakhabetheni, zenzelwe ukuletha ukuqeda okungenaphutha ngenkathi kuqinisekiswa ukuthi imiphetho yokusika ihlala ibukhali phakathi nokugijima isikhathi eside.

I-Huaxin Carbide: Ihola Imboni Ekukhiqizeni Imimese Eguqukayo

Umkhiqizi oyedwa ovelele wemimese yokushintshana esezingeni eliphezulu u-I-Huaxin Carbide, inkampani yaseShayina egxile ekukhiqizweni kwamathuluzi e-carbide okusebenza ngokhuni kanye nokusebenza ngensimbi. Eyaziwa ngemikhiqizo yayo enembile kanye nokusebenza kahle kakhulu, i-Huaxin Carbide ikhiqiza imimese eminingi yokushintshana, okuhlanganisaimimese yokuguqula i-carbide eqinile, Imimese yokuguqula enezimpondo ze-tungsten carbide, futhiimimese yokufaka i-carbide egobile. Ngokugxila ekuqineni nasekusikeni ngokunemba, i-Huaxin Carbide isibe ngumhlinzeki othembekile ezimbonini ezidinga amathuluzi okusika asezingeni eliphezulu emisebenzini yazo.

Imimese yokuguqula, ikakhulukazi leyo eyenziwe ngezinto ze-carbide kanye ne-tungsten carbide, inikeza ukusebenza okuphezulu kanye nokuphila isikhathi eside kwamathuluzi. Kungakhathaliseki ukuthi isetshenziswa ekusebenzeni ngokhuni, ekusebenzeni ngensimbi, noma kwezinye izinhlelo zokusebenza zokukhiqiza, le mimese inikeza izixazululo ezingabizi kakhulu nezisebenzayo zokusika ngokunemba.ama-blade aguqukayo, ukufakwa okubonakalayo, futhiimimese enezinhlangothi ezimbilikuzenza zibe usizo kakhulu ezindaweni ezinomthamo omkhulu. Abakhiqizi bathandaI-Huaxin Carbideziphambili ekuhlinzekeni la mathuluzi athuthukile, ziqinisekisa ukuthi izimboni emhlabeni wonke zingahlangabezana nezidingo zazo zokukhiqiza ngenkathi zigcina ikhwalithi nokusebenza kahle.

Isikhathi sokuthunyelwe: Novemba-13-2024