Ngokuthuthuka okuqhubekayo kwesayensi yezinto zokwakha, ukuthuthukiswa kanye nokusetshenziswa kwe-tungsten carbide ekhethekile engagqwali kuzokwandisa kakhulu ububanzi bokusetshenziswa kwama-tungsten carbide blades. Ngokufaka izakhi zokuhlanganisa, ukwenza ngcono izinqubo zokwelapha ukushisa, kanye nokuthuthukisa ubuchwepheshe bokwelashwa kwendawo, kulindeleke ukuthi ama-tungsten carbide blades esikhathi esizayo agcine ukusebenza okuhle kakhulu ezindaweni eziningi ezigqwalayo, anikeze izixazululo zokucubungula ezithembekile nezisebenzayo zezimboni ezahlukene.

1. Mayelana nama-Tungsten Carbide Blades

I-tungsten carbide, eyaziwa ngokuthi i-cemented carbide, iyinto eyenziwe nge-alloy eyakhiwe ngokuyinhloko yi-tungsten carbide, ekhiqizwa ngenqubo ye-powder metallurgy. Ibonakala ngokuqina okuphezulu kanye nokumelana okuhle kakhulu nokuguguleka, igcina ubulukhuni bayo bungashintshi ngisho noma ku-500°C futhi isenobulukhuni obukhulu ku-1000°C. Lokhu kusebenza okumangalisayo kwenza i-tungsten carbide ibe yisinqumo esihle kakhulu sokwenza amathuluzi okusika asebenza kahle kakhulu, asetshenziswa kabanzi kumathuluzi ahlukahlukene okusika afana namathuluzi e-lathe, okusika izigayo, okugaya, ama-planer, ama-drill, kanye namathuluzi okubhoboza.

Ama-blade e-tungsten carbide anamuhla akhiwe kakhulu yizingxenye ezimbili eziyisisekelo: i-tungsten carbide ne-cobalt. Isigaba esiqinile se-tungsten carbide sinikeza ubulukhuni obukhulu kanye nokumelana nokuguguleka okudingekayo ku-blade, kuyilapho isigaba se-cobalt binder sinikeza izinga elithile lokuqina kulokho okubalulekile. Ekwakhekeni kwe-blade ye-tungsten carbide evamile, i-tungsten carbide kanye ne-cobalt kubalwa u-99% wenani lonke, kanti ezinye izinsimbi zakha u-1%. Lesi sakhiwo esincane esiyingqayizivele sinikeza ama-blade e-tungsten carbide kokubili ubulukhuni obungatholakali ngensimbi esheshayo kanye nokumelana nokuguguleka okungaphezu kakhulu kokwensimbi yamathuluzi evamile, ebambe isikhundla esibalulekile emkhakheni wokucubungula ngomshini.

Ngokuthuthuka kwesayensi yezinto zokwakha, umndeni we-tungsten carbide uphinde wathuthukisa amazinga ahlukahlukene akhethekile, kufaka phakathi uchungechunge oluningi olufana ne-tungsten carbide engagugi kakhulu, i-tungsten carbide engathinteki kakhulu, i-tungsten carbide engamelani nokushisa okuphezulu, i-tungsten carbide engeyona i-magnetic, kanye ne-tungsten carbide enezinhlayiya ezincane kakhulu. Lezi zinto ze-tungsten carbide ezakhiwe ngendlela ehlukile zinikeza izixazululo ezilungiselelwe izimo ezahlukahlukene zohlelo lokusebenza. Isibonelo, i-tungsten carbide engamelani nokugqwala esetshenziswa ezindaweni zamakhemikhali ingangeza izinto ezixubayo njenge-chromium ne-nickel ukuze ithuthukise kakhulu izakhiwo zayo zokulwa nokugqwala.

Ukuqhathaniswa Kokusebenza Kwezinto Ezivamile Ze-Blade

| Uhlobo Lwezinto | Ubulukhuni (HRA) | Ukumelana Nokugqoka | Ukuqina | Ukumelana Nokugqwala |

| I-Tungsten Carbide Cemented Carbide | 89-95 | Kuphezulu Kakhulu | Okuphakathi nendawo | Okuphakathi kuya Kokuhle |

| Insimbi Esheshayo | 80-85 | Okuphakathi nendawo | Kuhle | Okuphakathi nendawo |

| Insimbi Yethuluzi | 70-75 | Okuphakathi nendawo | Kuhle | Okuphakathi nendawo |

| Ama-Blades e-Ceramic | 92-95 | Kuphezulu Kakhulu | Phansi | Kuhle kakhulu |

Ukuhlaziywa Kokusebenza Kokumelana Nokugqwala Kwe-Tungsten Carbide Blades

1. Izindlela kanye Nezimpawu Zokumelana Nokugqwala

Ukumelana nokugqwala kwama-tungsten carbide blades ngokuyinhloko kuvela ekwakhekeni kwawo okukhethekile kwamakhemikhali kanye nesakhiwo sawo esincane. I-tungsten carbide eyisisekelo iqukethe i-tungsten carbide kanye ne-cobalt. I-tungsten carbide ngokwayo inokuqina okukhulu kwamakhemikhali futhi ingamelana nokuguguleka yizinto ezahlukahlukene. Isigaba se-cobalt binder singakha futhi ungqimba lwe-oxide oluvikelayo ekushiseni kwegumbi, okuye kunciphise inqubo yokugqwala. Ekusetshenzisweni okungokoqobo, i-tungsten carbide ibonisa ukumelana okuthile nama-acid, ama-alkali, amanzi anosawoti, namanye amakhemikhali, okuvumela ukuthi igcine ukusebenza okuzinzile ezindaweni ezahlukahlukene zokugqwala.

Ucwaningo lubonisa ukuthi ukumelana nokugqwala kwe-tungsten carbide kuhle kakhulu ezindaweni ezithile. Isibonelo, ekuhlolweni kokugqwala kwe-aluminium liquid, izinga lokugqwala elimaphakathi le-tungsten emsulwa licishe libe yi-1/14 kuphela kunelensimbi ye-H13, okubonisa ukumelana okuhle kakhulu kokugqwala. Lokhu kusebenza okuphezulu kokulwa nokugqwala kwenza i-tungsten carbide ibe yindlela engcono kunensimbi yendabuko embonini ye-foundry kanye nezindawo zamakhemikhali ezishisa kakhulu. Ngokufanayo, ekuhlolweni kokugqwala kwama-alloy e-tungsten anamandla adonsela phansi aphezulu, abacwaningi bathole ukuthi lezi zinto ngokuvamile zinokumelana nokugqwala okuqinile, okugcina ubuqotho besakhiwo ngemuva kokuhlolwa kokugqwala kokucwiliswa kwelabhorethri kanye nokuhlolwa kokuchayeka endaweni yemvelo.

2. Izici Zomphezulu Nokuziphatha Kokugqwala

Ukumelana nokugqwala kwama-blade e-tungsten carbide akuxhomekile nje kuphela ezintweni ngokwazo kodwa futhi kakhulu esimweni sawo sobuso kanye nokucutshungulwa ngemva kokucubungula. Ubuso obucolekile nobucwebezelayo be-blade ye-tungsten carbide bungakha ungqimba oluvikelayo oluncane, luvimbele ngempumelelo ukungena kwemidiya egqwalisayo. Amanye ama-blade e-tungsten carbide aphezulu nawo asebenzisa ubuchwepheshe bokumboza ubuso (njenge-TiN, i-TiCN, i-DLC, njll.), okungagcini nje ngokuthuthukisa ukusebenza kokusika kwe-blade kodwa futhi kuthuthukisa kakhulu ukumelana nokugqwala.

Kubalulekile ukuqaphela ukuthi ukumelana nokugqwala kwe-tungsten carbide akuphelele. Izifundo zibonisa ukuthi ngaphansi kokuchayeka kwemvelo isikhathi eside, isigaba se-binder ezintweni ze-tungsten alloy sinokuthambekela okuthile kokugqwala, okungenzeka kuholele ekunciphiseni kwe-plasticity yezinto ezibonakalayo. Lesi simo sikhona futhi ku-tungsten carbide evamile enesigaba se-cobalt binder. Uma zisezindaweni ezithile ezigqwala njengomswakama kanye ne-salt spray, isigaba se-cobalt singagqwala ngokukhethekile, ngaleyo ndlela kuthinte ukusebenza kwe-blade iyonke. Ngakho-ke, ukukhetha amazinga e-tungsten carbide aphathwe ngokukhethekile amelana nokugqwala kubaluleke kakhulu ezimweni zokusetshenziswa ezinezingozi eziphezulu zokugqwala.

3. Intuthuko kanye Nentuthuko Ye-Tungsten Carbide Engamelani Nokugqwala

Ukuze kuhlangatshezwane nezidingo zohlelo lokusebenza ezindaweni ezibucayi njengezimboni zamakhemikhali nezasolwandle, ososayensi bezinto zokwakha bathuthukise amamodeli e-tungsten carbide aklanywe ngokukhethekile angagqwali. Lawa ma-tungsten carbide athuthukile athuthukisa kakhulu ukuzinza kwamakhemikhali kwezinto ngokufaka izinto ezixubayo njenge-chromium, i-nickel, ne-molybdenum efomini yendabuko. Isibonelo, i-patented cast chemical fiber blade engagqwali engagqwali ingagqwali i-sulfuric acid kunciphisa ngempumelelo ubuthakathaka be-tungsten carbide ngokwayo ngezinqubo ezikhethekile zokushisa, ukwakheka, kanye nokushisa, ngenkathi futhi kunikeza i-blade ukumelana okuhle nokugqwala kwe-sulfuric acid.

| Uhlobo Lwemvelo | Idigri Yokugqwala | Ifomu Eliyinhloko Lokugqwala | Ukusebenza |

| Indawo Ezungezile Yomkhathi | Phansi Kakhulu | Ukuncishiswa Kancane Kwe-Oxidation | Kuhle kakhulu |

| Indawo Ene-Acidic (pH<4) | Okuphakathi kuya Okuphezulu | Ukugqwala Okukhethiwe Kwesigaba Se-Binder | Kudinga Ibanga Elikhethekile |

| Indawo Ene-Alkaline (pH>9) | Okuphansi kuya Okuphakathi | Ukugqwala Komphezulu Ofanayo | Okuhle Kuya Kokuhle |

| Imvelo Yamanzi Nosawoti/Yasolwandle | Okuphakathi nendawo | Ukubhoboza, Ukugqwala Kwemifantu | Kudinga Izindlela Zokuzivikela |

| Insimbi Ebunjiwe Enokushisa Okuphezulu | Phansi | Ukusabela Kobuso Obuphakathi | Kuhle kakhulu |

Ukuziphatha Kokugqwala Kwezinto Ze-Tungsten Carbide Ezindaweni Ezihlukene

Ukuhlaziywa Kokufaneleka Kwemvelo: Izimo Lapho Ama-Tungsten Carbide Blades Excel

Mayelana neHuaxin: Umkhiqizi Wemimese Yokusika Ene-Cemented Tungsten Carbide

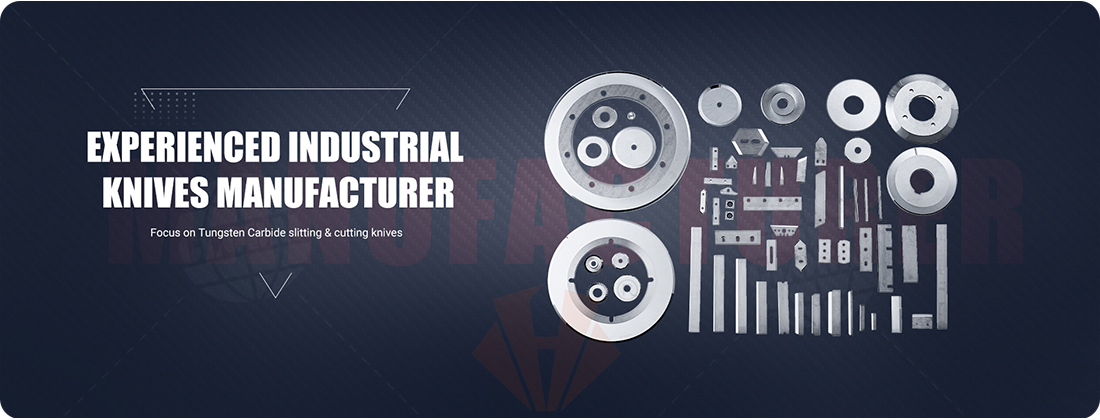

I-CHENGDU HUAXIN CEMENTED CARBIDE CO., LTD ingumhlinzeki ochwepheshe kanye nomkhiqizi wemikhiqizo ye-tungsten carbide, njengemimese yokufaka i-carbide yokwenza ukhuni, imimese eyindilinga ye-carbide yokusika izinduku zokuhlunga ugwayi nogwayi, imimese eyindilinga yokusika amakhadibhodi anezimbobo ezintathu, ama-razor blades/ama-slotted blades okupakisha, i-tape, ukusika ifilimu encane, ama-fiber cutter blades embonini yezindwangu njll.

Njengoba sekuyiminyaka engaphezu kwengu-25 sithuthukisa imikhiqizo yethu, ithunyelwe kwamanye amazwe e-US A, Russia, South America, India, Turkey, Pakistan, Australia, Southeast Asia njll. Ngekhwalithi enhle kakhulu namanani ancintisanayo, isimo sethu sengqondo sokusebenza kanzima kanye nokuphendula kuyavunyelwa amakhasimende ethu. Futhi singathanda ukwakha ubudlelwano obusha bebhizinisi namakhasimende amasha.

Xhumana nathi namuhla futhi uzojabulela izinzuzo zekhwalithi enhle kanye nezinsizakalo ezivela emikhiqizweni yethu!

Imikhiqizo yezimboni ze-tungsten carbide esebenza kahle kakhulu

Isevisi Yangokwezifiso

I-Huaxin Cemented Carbide ikhiqiza ama-blade e-tungsten carbide enziwe ngokwezifiso, ama-blank ashintshiwe ajwayelekile najwayelekile kanye nama-preform, kusukela ku-powder kuya kuma-blank aqediwe. Ukukhetha kwethu okuphelele kwama-grade kanye nenqubo yethu yokukhiqiza kunikeza njalo amathuluzi asebenza kahle kakhulu, athembekile acishe abe yi-net abhekana nezinselele ezikhethekile zokusetshenziswa kwamakhasimende kuzo zonke izimboni ezahlukahlukene.

Izixazululo Ezilungiselelwe Yonke Imboni

ama-blade aklanywe ngokwezifiso

Umkhiqizi ohamba phambili wama-blade ezimboni

Imibuzo evamile yamakhasimende kanye nezimpendulo ze-Huaxin

Lokho kuncike enanini, ngokuvamile izinsuku ezi-5-14. Njengomkhiqizi wezinsika zezimboni, i-Huaxin Cement Carbide ihlela ukukhiqizwa ngama-oda kanye nezicelo zamakhasimende.

Ngokuvamile amasonto ama-3-6, uma ucela imimese yomshini eyenziwe ngokwezifiso noma ama-blade ezimboni angekho esitokweni ngesikhathi sokuthenga. Thola i-Sollex Purchase & Delivery Conditions lapha.

uma ucela imimese yomshini eyenziwe ngokwezifiso noma ama-blade ezimboni angekho esitokweni ngesikhathi sokuthenga. Thola Izimo Zokuthenga Nokulethwa ze-Sollexlapha.

Ngokuvamile i-T/T, i-Western Union...idiphozithi kuqala, Wonke ama-oda okuqala avela kumakhasimende amasha akhokhelwa kusengaphambili. Ama-oda engeziwe angakhokhwa nge-invoyisi...Xhumana nathiukwazi okwengeziwe

Yebo, xhumana nathi, imimese yezimboni iyatholakala ngezindlela ezahlukene, kufaka phakathi imimese enesitsha esiphezulu, imimese eyindilinga engezansi, imimese enezinyo ezigobile/ezinamazinyo, imimese ebhoboza nxazonke, imimese eqondile, imimese ye-guillotine, imimese ecijile, imimese ye-razor engunxande, kanye nemimese ye-trapezoidal.

Ukuze sikusize uthole i-blade engcono kakhulu, i-Huaxin Cement Carbide ingakunikeza ama-blade amaningana amasampula ongawahlola ekukhiqizweni. Ukuze usike futhi uguqule izinto eziguquguqukayo njengefilimu yepulasitiki, i-foil, i-vinyl, iphepha, nokunye, sinikeza ama-blade okuguqula kufaka phakathi ama-slitter blade anezikhala kanye nama-razor blade anezikhala ezintathu. Sithumelele umbuzo uma unentshisekelo kuma-blade omshini, futhi sizokunikeza isipho. Amasampula emimese eyenziwe ngokwezifiso awatholakali kodwa wamukelekile uku-oda inani elincane kakhulu le-oda.

Kunezindlela eziningi ezizokwandisa isikhathi eside kanye nokuphila kweshelufu kwemimese yakho yezimboni kanye nama-blade esitokweni. Xhumana nathi ukuze wazi ukuthi ukupakishwa okufanele kwemimese yomshini, izimo zokugcina, umswakama kanye nokushisa komoya, kanye nokwembozwa okwengeziwe kuzovikela imimese yakho futhi kugcine ukusebenza kwayo kokusika.

Isikhathi sokuthunyelwe: Okthoba-11-2025