TUhlelo Lwamathuluzi Okuzungeza/Ukuthunga kanye Nama-Blades Awo Emsebenzini Wokhuni

Emkhakheni wokusebenza ngokhuni, ukungezwa kokuthungwa kanye nemigqa egobile ezingcezwini eziguquliwe akugcini nje ngokukhanga okubonakalayo kodwa futhi nesithakazelo esithintayo, kuguqula amafomu alula abe imisebenzi yobuciko. Amathuluzi e-System of Spiralling/Texturing ayisethi ekhethekile yamathuluzi aklanyelwe ukuthuthukisa amaphrojekthi okuthungwa ngokhuni ngamaphethini ayinkimbinkimbi, imigqa egobile, kanye nokuthungwa. Lapha, sihlola lolu hlelo, izingxenye zalo, nokuthi kungani ama-blade e-tungsten carbide eyisinqumo esihle kakhulu kula mathuluzi.

Ukuqonda Uhlelo Lokujikeleza/Ukubhala

Ukubuka Konke Kwamathuluzi Okuzungeza Nokubhala:

Ithuluzi Lokuthungela: Leli thuluzi lengeza ukuthungela okuhlukile ebusweni bokhuni, lidala imiphumela efana ne-striations, i-whorls, noma ukuqeda kwe-orange peel. Ngokuvamile linesikhiphi esishintshashintshayo esingasebenza kokubili ezithambile kanye nasezingodweni eziqinile, yize umphumela ungahluka ngokuya ngokusanhlamvu kokhuni kanye nobuningi.

Ithuluzi Lokuzungeza: Njengoba lisetshenziselwa ukudala imiklamo noma imibhobho, la mathuluzi angakhiqiza imiklamo yokujikeleza yesandla sobunxele nesokudla. Ngokuvamile iza nesistimu ehlanganisa ukuphumula kwamathuluzi anezikhundla ezikhonjisiwe ukuze kuphindaphindwe njalo imiklamo yokujikeleza. Ubukhulu obuhlukene bokujikijela bungatholakala ngokushintsha umsiki noma ukulungisa i-engeli yethuluzi.

Izingxenye Eziyinhloko:

- Isibambo: Ngokuvamile senziwe ngokhuni ukuze kube nenduduzo nokulawula, okuvumela ukusetshenziswa isikhathi eside ngaphandle kokukhathala.

- Ukuphumula Kwamathuluzi: Ingxenye ebalulekile yesistimu yokuzungeza, evumela ukulawula okunembile phezu kwe-engeli kanye nokujula kokusikwa.

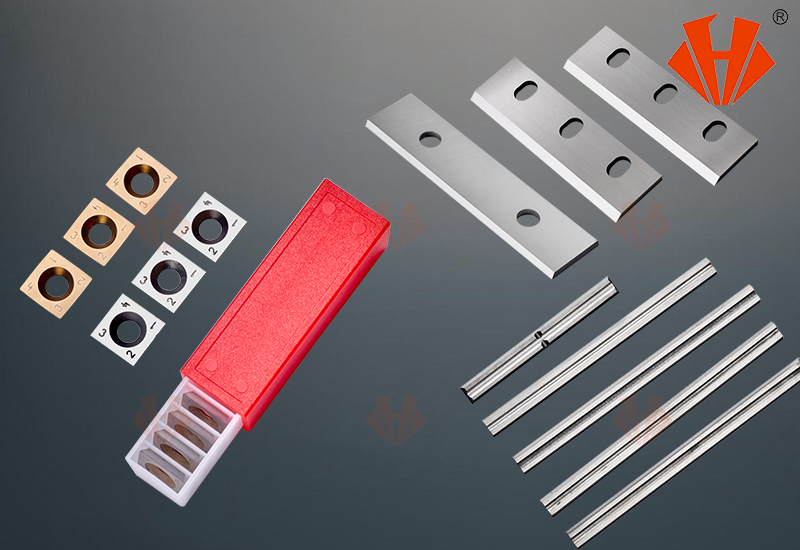

- Abasiki: Inhliziyo yala mathuluzi, atholakala ngezindlela ezahlukene:

- Izicucu Zokuthungela: Lezi ziza ngomklamo owodwa noma ngaphezulu, ngokuvamile zinomphetho ophindwe kabili noma iphrofayili ethile ukudala ukuthungwa okuhlukile.

- Izisiki Ezijikelezayo: Zitholakala ngamasethi, ngokuvamile zihlanganisa ama-pitch ahlukene (njenge-2mm, 4mm, 6mm) ukuze kufezwe imiphumela ehlukahlukene yokuzungeza.

Inzuzo Yama-Tungsten Carbide Blades

Uma kukhulunywa ngama-blades asetshenziswa kumathuluzi okuhlanganisa nokubhala, i-tungsten carbide ivelele njengento ekhethwayo ngezizathu eziningana eziphoqelelayo:

Ukuqina:

I-tungsten carbide yaziwa ngobulukhuni bayo (idlula idayimane kuphela), okusho ukuthi lawa ma-blade agcina unqenqema lwawo lude kakhulu kune-blade yensimbi yendabuko. Lokhu kuqina kuhumusha impilo yamathuluzi ende, kunciphisa ukuvama kokufakwa esikhundleni nokulolwa.

Ukugcinwa Komphetho:

Ukugcinwa okuphezulu komphetho we-tungsten carbide kuqinisekisa ukuthi ukusika ngakunye kuhlala kunembile ngokuhamba kwesikhathi, okubalulekile ekufezeni amaphethini okubhala kanye nokujika okuvumelanayo. Leli khwalithi liwusizo kakhulu ekusebenzeni ngokhuni lapho ukunemba kungenza umehluko omkhulu wobuhle.

Ukuguquguquka:

Lezi zinsika zingasika izinhlobo ezahlukene zezinkuni, kusukela kokuthambile kuya kokuqinile, ngaphandle kokulahlekelwa ubukhali bazo ngokushesha. Ukuguquguquka kwazo kuzenza zilungele ochwepheshe abasebenza ngezinhlobo ezahlukene zezinkuni namaphrojekthi.

Ukulungiswa Okuncishisiwe:

Nakuba ama-blade e-tungsten carbide kungaba nzima kakhulu ukuwalola ngenxa yobunzima bawo, isidingo sokuwalola asivamile kakhulu. Lesi sici sikhanga kakhulu kulabo abafuna ukunciphisa isikhathi sokungasebenzi kanye nezindleko zokulungisa.

Ukusebenza kahle:

Ikhono lokusika ukhuni ngokuhlanzekile ngomzamo omncane aligcini nje ngokusheshisa inqubo kodwa futhi linciphisa ukucindezeleka ngokomzimba kumuntu osebenza ngokhuni, okuvumela imiklamo eyinkimbinkimbi kakhulu ngomzamo omncane.

Izicelo kanye Nezinto Okufanele Uzicabangele

- Izicelo: Lawa mathuluzi asetshenziselwa ukuhlobisa izinto eziguquliwe njengezimbiza, izipini, izibani, nezitsha, okuhlinzeka ngesici sokuhlobisa esingaba sobala noma sibizwe ngokusekelwe ebuchwephesheni nasethuluzini elisetshenzisiwe.

- Okubalulekile: Nakuba ama-tungsten carbide blades ewutshalomali oluhle kakhulu, eza nezindleko zokuqala eziphezulu. Kodwa-ke, ukuhlala isikhathi eside nokusebenza kwawo kuvame ukuthethelela lokhu kusetshenziswa. Futhi, abasebenzisi kufanele baqaphele isidingo sezinyathelo zokuphepha ezifanele lapho besebenza ngala mathuluzi ngenxa yobukhali bawo kanye nothuli lwezinkuni oluvela kuwo.

TUhlelo Lwamathuluzi Okusonta/Ukuthunga, oluhlonyiswe ngama-tungsten carbide blades, lumelela iqophelo eliphezulu kubuchwepheshe bamathuluzi okusebenza ngokhuni, lunikeza ukulawula okungenakuqhathaniswa, ukunemba, kanye nokuqina. Kungakhathaliseki ukuthi ungumguquli wokhuni ochwepheshe noma ungumuntu othanda ukuzilibazisa, ukutshala imali kula mathuluzi kungaphakamisa kakhulu amaphrojekthi akho okuguqula ngokhuni, kunikeze izinzuzo zobuciko kanye nokusebenza. Khumbula, ukukhetha izinto zama-blades akho kubaluleke kakhulu njengobuchwepheshe; i-tungsten carbide ayigcini nje ngokumela umsebenzi kodwa futhi iyazikhandla kuwo.

Imimese ye-Planer Blades eguqukayoZenziwe nge-carbide grade yekhwalithi ephezulu futhi zihlolwa ngazinye ukuqinisekisa ikhwalithi nokunemba. Ama-planer blades asetshenziswa lapho kusetshenzwa ezindaweni zokhuni ukusiza ekudaleni izindawo ezihlelwe kahle. Angasetshenziswa futhi ukuxubha, nokubuyisela imiphetho. Ubukhulu be-blade bubhekisela kubukhulu be-planer ezolingana nayo. Izohlala isikhathi eside kune-HSS blades evamile okungenani izikhathi ezingu-20 futhi ikhiqize ukuphela okubushelelezi nokuhlanzekile.

Abakhiqizi be-Huaxin Cemented Carbideama-blade e-tungsten carbideama-blank nama-preforms enziwe ngokwezifiso, ashintshiwe ajwayelekile kanye najwayelekile, kusukela ku-powder kuya kuma-blank aqediwe. Ukukhetha kwethu okuphelele kwama-grade kanye nenqubo yethu yokukhiqiza kunikeza njalo amathuluzi asebenza kahle kakhulu, athembekile acishe abe yi-net abhekana nezinselele ezikhethekile zokusetshenziswa kwamakhasimende kuzo zonke izimboni ezahlukahlukene.

Izixazululo Ezilungiselelwe Yonke Imboni

ama-blade aklanywe ngokwezifiso

Umkhiqizi ohamba phambili wama-blade ezimboni

www.huaxincarbide.com

contact: lisa@hx-carbide.com

Isikhathi sokuthunyelwe: Jan-11-2025