Woza uzofunda nge-HSS

Insimbi yesivinini esiphezulu (i-HSS) iyinsimbi yethuluzi enobulukhuni obuphezulu, ukumelana nokuguguleka okuphezulu kanye nokumelana nokushisa okuphezulu, eyaziwa nangokuthi insimbi yomoya noma insimbi ebukhali, okusho ukuthi iyaqina ngisho noma ipholile emoyeni ngesikhathi sokucinywa futhi ibukhali. Ibizwa nangokuthi insimbi emhlophe.

Insimbi yesivinini esikhulu iyinsimbi ye-alloy enokwakheka okuyinkimbinkimbi equkethe izinto ezakha i-carbide njenge-tungsten, i-molybdenum, i-chromium, i-vanadium ne-cobalt. Inani eliphelele lezinto ezixubile lifinyelela cishe ku-10 kuya ku-25%. Ingagcina ubulukhuni obuphezulu ngaphansi kokushisa okuphezulu (cishe ku-500℃) ekusikeni kwesivinini esikhulu, i-HRC ingaba ngaphezu kuka-60. Lesi yisici esibaluleke kakhulu se-HSS - ubulukhuni obubomvu. Futhi insimbi yamathuluzi e-carbon ngokucisha kanye nokushisa okuphansi, ekushiseni kwegumbi, yize kukhona ubulukhuni obuphezulu kakhulu, kodwa lapho izinga lokushisa liphakeme kuno-200 ℃, ubulukhuni buzokwehla kakhulu, ku-500 ℃ ubulukhuni bube sezingeni elifanayo nesimo esifakwe emanzini, balahlekelwa ngokuphelele ikhono lokusika insimbi, okunciphisa amathuluzi okusika insimbi yamathuluzi e-carbon. Futhi insimbi yesivinini esikhulu ngenxa yobulukhuni obuhle obubomvu, ukuze kulungiswe amaphutha abulalayo ensimbi yamathuluzi e-carbon.

Insimbi yesivinini esikhulu isetshenziswa kakhulu ukukhiqiza amathuluzi okusika ensimbi ayinkimbinkimbi anomphetho omncane futhi amelana nokushayisana, kodwa futhi nokukhiqiza amabheringi okushisa okuphezulu kanye nama-cold extrusion dies, njengamathuluzi okujika, ama-drill, ama-hobs, ama-machine saw blades kanye nama-dae adinga amandla.

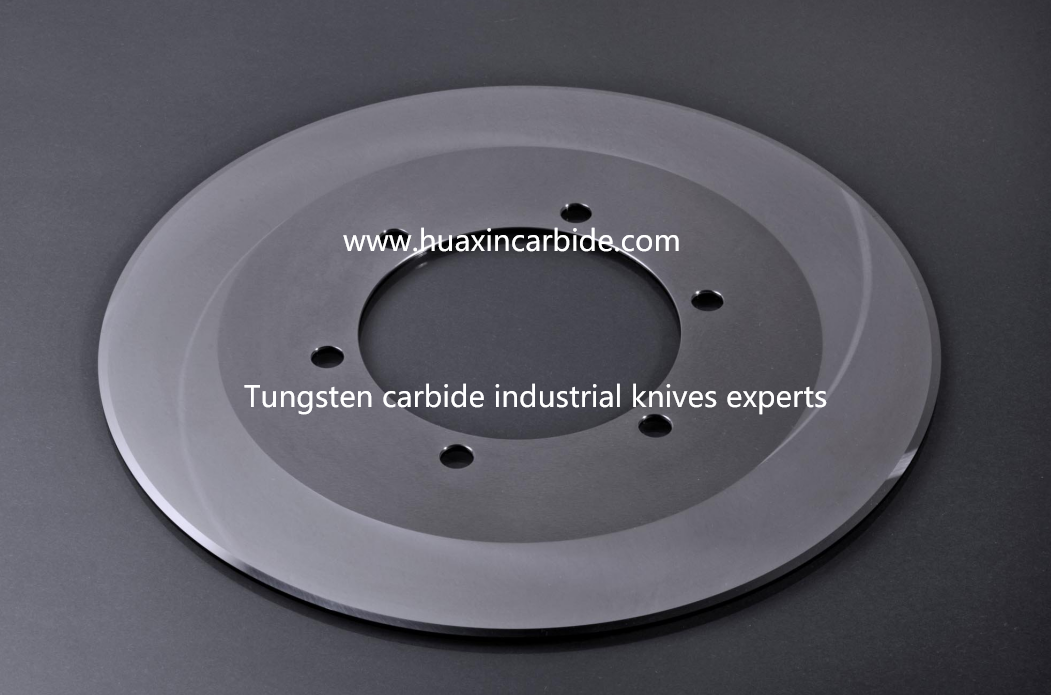

Woza uzofunda ngensimbi ye-tungsten

Insimbi ye-tungsten (i-carbide) inezici eziningi ezinhle kakhulu njengokuqina okuphezulu, ukumelana nokuguguleka, amandla nokuqina okungcono, ukumelana nokushisa, ukumelana nokugqwala, njll. Ikakhulukazi ubunzima bayo obukhulu kanye nokumelana nokuguguleka akushintshi ngisho noma izinga lokushisa lingu-500℃, futhi kusenokuqina okuphezulu ku-1000℃.

Insimbi ye-tungsten, ezingxenye zayo eziyinhloko ziyi-tungsten carbide kanye ne-cobalt, ihlanganisa u-99% wazo zonke izingxenye kanye no-1% wezinye izinsimbi, ngakho-ke ibizwa ngokuthi insimbi ye-tungsten, eyaziwa nangokuthi i-cemented carbide, futhi ibhekwa njengamazinyo embonini yanamuhla.

Insimbi ye-tungsten iyinto ehlanganisiwe equkethe okungenani ukwakheka kwe-carbide yensimbi eyodwa. I-tungsten carbide, i-cobalt carbide, i-niobium carbide, i-titanium carbide, kanye ne-tantalum carbide yizingxenye ezivamile zensimbi ye-tungsten. Usayizi wezinhlamvu zengxenye ye-carbide (noma isigaba) ngokuvamile uphakathi kwama-microns angu-0.2-10, kanti izinhlamvu ze-carbide zihlanganiswa ndawonye kusetshenziswa i-metal binder. Izinsimbi ezibophayo ngokuvamile ziyizinsimbi zeqembu lensimbi, ngokuvamile i-cobalt kanye ne-nickel. Ngakho-ke kukhona ama-alloy e-tungsten-cobalt, ama-alloy e-tungsten-nickel kanye nama-alloy e-tungsten-titanium-cobalt.

Ukwakha i-tungsten sinter kuwukucindezela i-powder ibe yi-billet, bese uyibeka esithandweni sokushisa ukuze uyishise kuze kufike ezingeni lokushisa elithile (izinga lokushisa lokushisisa) bese uyigcina isikhathi esithile (isikhathi sokubamba), bese uyipholisa ukuze uthole izinto zensimbi ze-tungsten ezinezakhiwo ezidingekayo.

①I-tungsten ne-cobalt cemented carbide

Ingxenye eyinhloko yi-tungsten carbide (WC) kanye ne-binder cobalt (Co). Ibanga lakhiwe yi-“YG” (“i-cobalt eqinile” ku-Hanyu Pinyin) kanye nephesenti lokuqukethwe kwe-cobalt okumaphakathi. Isibonelo, i-YG8, okusho ukuthi isilinganiso se-WCo = 8% kanti okusele yi-tungsten carbide cemented carbide.

②I-tungsten, i-titanium kanye ne-cobalt cemented carbide

Izingxenye eziyinhloko yi-tungsten carbide, i-titanium carbide (TiC) kanye ne-cobalt. Ibanga lakhiwe yi-“YT” (“i-hard, titanium” ku-Hanyu Pinyin) kanye nokuqukethwe okumaphakathi kwe-titanium carbide. Isibonelo, i-YT15, isho isilinganiso se-TiC=15%, okusele yi-tungsten carbide kanye nokuqukethwe kwe-cobalt kwe-tungsten titanium cobalt carbide.

③I-Tungsten-titanium-tantalum (niobium) carbide

Izingxenye eziyinhloko yi-tungsten carbide, i-titanium carbide, i-tantalum carbide (noma i-niobium carbide) kanye ne-cobalt. Lolu hlobo lwe-carbide lubizwa nangokuthi i-carbide ejwayelekile noma i-universal carbide. Ibanga liqukethe u-“YW” (“olukhuni” kanye no-“million” ku-Hanyu Pinyin) kanye nenombolo elandelanayo, njenge-YW1.

Insimbi ye-tungsten inezici eziningi ezinhle kakhulu njengokuqina okuphezulu, ukumelana nokuguguleka, amandla nokuqina okungcono, ukumelana nokushisa, ukumelana nokugqwala, njll. Ikakhulukazi ubulukhuni bayo obuphezulu kanye nokumelana nokuguguleka akushintshi ngisho noma izinga lokushisa lingu-500℃, futhi kusenobulukhuni obuphezulu ku-1000℃. I-carbide esimende isetshenziswa kabanzi njengezinto zokwakha, njengamathuluzi okujika, amathuluzi okugaya, ama-drill, amathuluzi okubhoboza, njll. Ijubane lokusika le-carbide entsha lilingana nezikhathi ezingamakhulu kunensimbi yekhabhoni.

Isikhathi sokuthunyelwe: Feb-21-2023