Inqubo Yokukhiqiza I-Carbide Ene-Cemented Ngokuvamile kuthiwa ukuze kuthuthukiswe ukusebenza kahle kwemishini, amapharamitha amathathu okusika abalulekile—isivinini sokusika, ukujula kokusikwa, kanye nesilinganiso sokudla—kumele kwenziwe ngcono, njengoba lokhu ngokuvamile kuyindlela elula neqondile kakhulu. Kodwa-ke, ukwandisa la mapharamitha kuvame ukulinganiselwa yizimo zamathuluzi omshini akhona. Ngakho-ke, indlela engabizi kakhulu futhi elula ukukhetha ithuluzi elifanele. Amathuluzi e-carbide ane-cemented okwamanje ayinto eyinhloko emakethe yamathuluzi. Ikhwalithi ye-carbide ene-cemented inqunywa yizici ezintathu: i-carbide matrix ene-cemented (skeleton), isakhiwo kanye nesimo se-blade (inyama), kanye nokugqoka (isikhumba). Namuhla, sizohlola ngokujulile amathuluzi okusebenza, kusukela "ku-skeleton kuya enyameni." Ukwakheka kwe-Carbide Matrix Ene-Cemented I-carbide matrix ene-cemented iqukethe izingxenye ezimbili eziyinhloko:

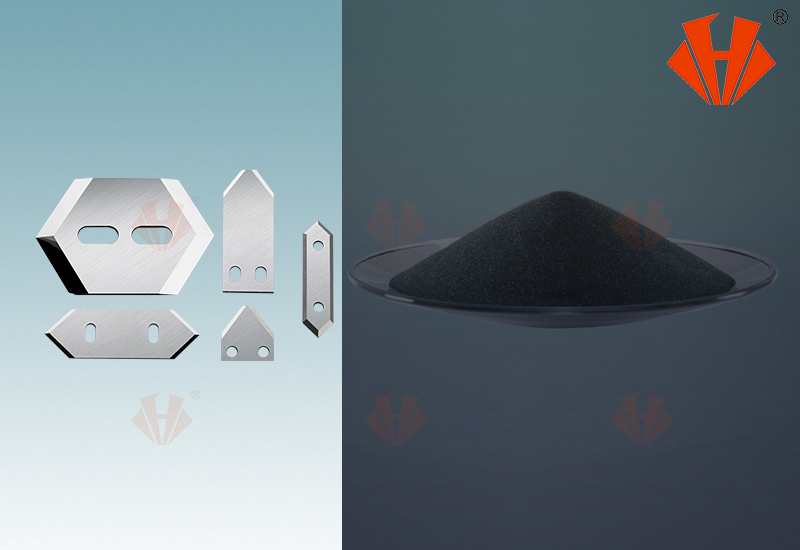

Isigaba Sokuqina: Lokhu kufaka phakathi izinto ezifana ne-tungsten carbide (WC) kanye ne-titanium carbide (TiC), eziqala njengezimpushana.

Ungazithathi kalula lezi zimpushana—ziyizinto eziyinhloko zokusetshenziswa kwazo zonke izinhlayiya ze-carbide ezifakwe usimende.

Ukukhiqizwa kwe-Tungsten Carbide:I-tungsten carbide yenziwe nge-tungsten ne-carbon. Impuphu ye-tungsten enobukhulu obuphakathi kwezinhlayiya ezingu-3–5 μm ixutshwa ne-carbon black emshinini wokugaya ukuze ixutshwe kahle. Ngemva kokuxuba kahle, ingxube ifakwa kuthreyi ye-graphite bese ishiswa esithandweni sokumelana ne-graphite ku-1400–1700°C. Kuleli zinga lokushisa eliphakeme, ukusabela kukhiqiza i-tungsten carbide.

Izakhiwo:I-tungsten carbide iyinto eqinile kakhulu kodwa ebuthakathaka enezinga lokuncibilika elingaphezu kuka-2000°C, ngezinye izikhathi elidlula u-4000°C. Inquma ubulukhuni obuphezulu be-alloy kanye nokumelana nokuguguleka.

Insimbi Ehlanganisiwe: Ngokuvamile, kusetshenziswa izinsimbi zeqembu lensimbi ezifana ne-cobalt (Co) kanye ne-nickel (Ni), kanti i-cobalt iyona evame kakhulu ekusetshenzisweni kwemishini.

Isibonelo, uma i-tungsten carbide ixutshwa ne-cobalt, okuqukethwe yi-cobalt kubaluleke kakhulu ezimpahleni ze-carbide eqinisiwe. Okuqukethwe okuphezulu kwe-cobalt kuthuthukisa ukuqina, kuyilapho okuqukethwe okuphansi kwe-cobalt kuthuthukisa ubulukhuni kanye nokumelana nokuguguleka.

Inqubo Yokukhiqiza

1. Ukulungiswa Kwempuphu (Ukugaya Okumanzi) Ekamelweni lokugaya, izinto zokusetshenziswa ziyagaywa zibe usayizi wezinhlayiya ozifunayo endaweni ene-ethanol, amanzi, kanye nezihlanganisi zezinto eziphilayo. Le nqubo, eyaziwa ngokuthi ukugaya okumanzi, ihilela ukwengeza izinyibilikisi eziphilayo noma ezingaphili njengezinsiza zokugaya.

▶ Kungani Kugaywa Ngokumanzi?

▶Ukugaya okomile kungagaya izinto kuphela ezingeni le-micron (isb., ngaphezu kwama-20 μm) ngoba, ngaphansi kwalesi sayizi, ukukhangana kwe-electrostatic kubangela ukuhlangana okukhulu kwezinhlayiya, okwenza ukugaya okuqhubekayo kube nzima.

▶Ukugaya okumanzi, okunomthelela wezinsiza zokugaya, kunganciphisa usayizi wezinhlayiya ube ama-micron ambalwa noma ngisho nama-nanometer.

▶Ubude: Kuye ngezinto zokusetshenziswa, ukugaya okumanzi kuthatha cishe amahora angu-8-55, okuholela ekumisweni okufanayo kwezinto zokusetshenziswa.

2. Ukomisa Ngokufutha Ingxube yoketshezi ipompelwa emshinini wokomisa ngokufutha, lapho igesi ye-nitrogen eshisayo ikhipha khona i-ethanol namanzi, ishiye impuphu enobukhulu obufanayo.

▶Impuphu eyomisiwe yakhiwe yizinhlayiya eziyindilinga ezinobubanzi obusukela ku-20–200 μm. Ukuze sikubeke kahle lokhu, impuphu engcono kakhulu ingaphansi kwengxenye yobukhulu bezinwele zomuntu.

▶Udaka olomisiwe luthunyelwa ukuze luhlolwe ikhwalithi ukuqinisekisa ukuhambisana.

3. UkucindezelaImpuphu ehloliwe ifakwa emshinini wokucindezela ukuze kwenziwe izinto zokufaka amathuluzi.

▶Isikhunta sokucindezela sifakwa emshinini, bese i-punch ne-die zilawulwa ukuze kucindezelwe i-powder ibe yisimo nosayizi oyisisekelo wethuluzi.

▶Kuye ngohlobo lokufakwa, ingcindezi edingekayo ingafinyelela ku-12 amathani.

▶Ngemva kokucindezela, ukufakwa ngakunye kuyalinganiswa ukuqinisekisa ikhwalithi nokunemba.

4. UkuhlikihlaIzicucu ezisanda kucindezelwa zibuthakathaka kakhulu futhi zidinga ukuqina esithandweni sokuhlikihla.

▶Izinto ezifakiwe zidlula amahora angu-13 okwelashwa ngokushisa ku-1500°C, lapho i-cobalt encibilikisiwe ihlangana khona nezinhlayiya ze-tungsten carbide. Ku-1500°C, insimbi ingancibilika ngokushesha njengoshokoledi.

▶Ngesikhathi sokusila, i-polyethylene glycol (PEG) engxubeni iyahwamuka, futhi ivolumu yento efakiwe iyancipha cishe ngo-50%, kufinyelelwe izinga elithile lobulukhuni.

5. Ukwelashwa Komphezulu (Ukucija Nokumboza) Ukuze kufezwe ubukhulu obuqondile, izinto ezifakiwe ziyacijiswa ukuze zigaye izindawo eziphezulu nezingezansi.

▶Njengoba izifakelo ze-carbide ezisikiwe ziqinile kakhulu, amasondo okugaya amadayimane ezimboni asetshenziselwa ukugaya ngokunembile.

▶Lesi sinyathelo sidinga ukunemba okuphezulu kubuchwepheshe bokugaya. Isibonelo, iSweden isebenzisa ubuchwepheshe bokugaya obuthuthukisiwe obuyi-6-axis ukuze ihlangabezane nezidingo zokubekezelelana eziqinile kakhulu.

Ngemva kokugaya, izinto ezifakiwe ziyahlanzwa, zimbozwe, bese zihlolwa ikhwalithi yokugcina.

Kungani Ukhethe iChengduhuaxin Carbide?

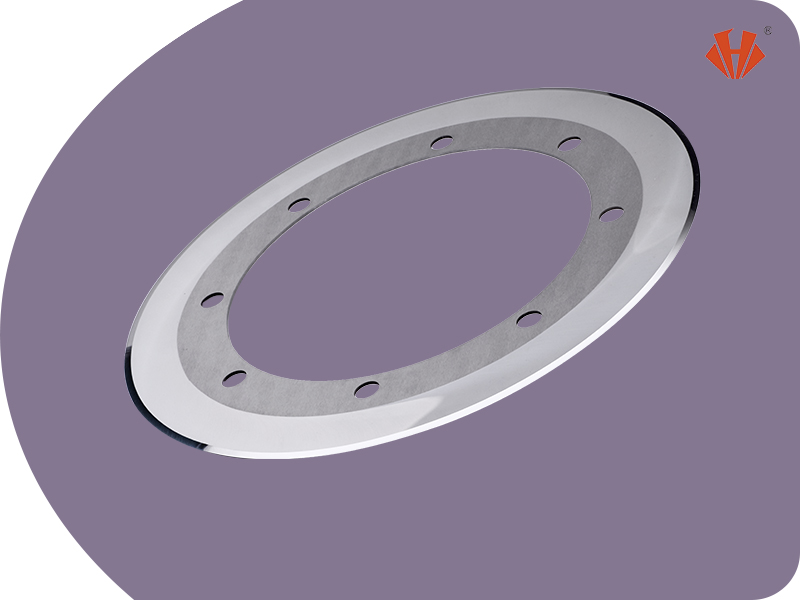

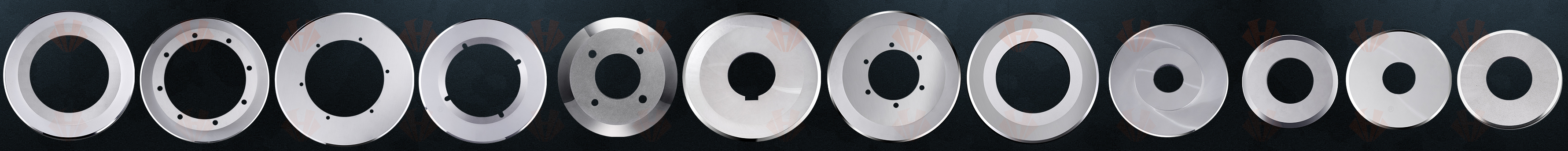

I-Chengduhuaxin Carbide ivelele emakethe ngenxa yokuzibophezela kwayo ekhwalithini nasekusunguleni izinto ezintsha. Ama-blade abo ekhaphethi e-tungsten carbide kanye nama-blade e-tungsten carbide aklanyelwe ukusebenza kahle kakhulu, anikeza abasebenzisi amathuluzi ahlinzeka ngokusika okuhlanzekile nokunembile ngenkathi ebekezelela ubunzima bokusetshenziswa kakhulu kwezimboni. Ngokugxila ekuqineni nasekusebenzeni kahle, ama-blade e-Chengduhuaxin Carbide anikeza ikhambi elifanele izimboni ezidinga amathuluzi okusika anokwethenjelwa.

I-CHENGDU HUAXIN CEMENTED CARBIDE CO.,LTD ingumhlinzeki ochwepheshe kanye nomkhiqizi weimikhiqizo ye-tungsten carbide,njengemimese yokufaka i-carbide yokusebenza ngokhuni, i-carbideimimese eyindilingangobaizinduku zokuhlunga ugwayi nogwayi, imimese eyindilinga ukusika amakhadibhodi ane-corugat,ama-razor blades/ama-slotted blades anezimbobo ezintathu ukupakisha, iteyipu, ukusika ifilimu encane, ama-fiber cutter blades embonini yezindwangu njll.

Njengoba sekuyiminyaka engaphezu kwengu-25 sithuthukisa imikhiqizo yethu, ithunyelwe kwamanye amazwe e-US A, Russia, South America, India, Turkey, Pakistan, Australia, Southeast Asia njll. Ngekhwalithi enhle kakhulu namanani ancintisanayo, isimo sethu sengqondo sokusebenza kanzima kanye nokuphendula kuyavunyelwa amakhasimende ethu. Futhi singathanda ukwakha ubudlelwano obusha bebhizinisi namakhasimende amasha.

Xhumana nathi namuhla futhi uzojabulela izinzuzo zekhwalithi enhle kanye nezinsizakalo ezivela emikhiqizweni yethu!

Imibuzo evamile yamakhasimende kanye nezimpendulo ze-Huaxin

Lokho kuncike enanini, ngokuvamile izinsuku ezi-5-14. Njengomkhiqizi wezinsika zezimboni, i-Huaxin Cement Carbide ihlela ukukhiqizwa ngama-oda kanye nezicelo zamakhasimende.

Ngokuvamile amasonto ama-3-6, uma ucela imimese yomshini eyenziwe ngokwezifiso noma ama-blade ezimboni angekho esitokweni ngesikhathi sokuthenga. Thola i-Sollex Purchase & Delivery Conditions lapha.

uma ucela imimese yomshini eyenziwe ngokwezifiso noma ama-blade ezimboni angekho esitokweni ngesikhathi sokuthenga. Thola Izimo Zokuthenga Nokulethwa ze-Sollexlapha.

Ngokuvamile i-T/T, i-Western Union...idiphozithi kuqala, Wonke ama-oda okuqala avela kumakhasimende amasha akhokhelwa kusengaphambili. Ama-oda engeziwe angakhokhwa nge-invoyisi...Xhumana nathiukwazi okwengeziwe

Yebo, xhumana nathi, imimese yezimboni iyatholakala ngezindlela ezahlukene, kufaka phakathi imimese enesitsha esiphezulu, imimese eyindilinga engezansi, imimese enezinyo ezigobile/ezinamazinyo, imimese ebhoboza nxazonke, imimese eqondile, imimese ye-guillotine, imimese ecijile, imimese ye-razor engunxande, kanye nemimese ye-trapezoidal.

Ukuze sikusize uthole i-blade engcono kakhulu, i-Huaxin Cement Carbide ingakunikeza ama-blade amaningana amasampula ongawahlola ekukhiqizweni. Ukuze usike futhi uguqule izinto eziguquguqukayo njengefilimu yepulasitiki, i-foil, i-vinyl, iphepha, nokunye, sinikeza ama-blade okuguqula kufaka phakathi ama-slitter blade anezikhala kanye nama-razor blade anezikhala ezintathu. Sithumelele umbuzo uma unentshisekelo kuma-blade omshini, futhi sizokunikeza isipho. Amasampula emimese eyenziwe ngokwezifiso awatholakali kodwa wamukelekile uku-oda inani elincane kakhulu le-oda.

Kunezindlela eziningi ezizokwandisa isikhathi eside kanye nokuphila kweshelufu kwemimese yakho yezimboni kanye nama-blade esitokweni. Xhumana nathi ukuze wazi ukuthi ukupakishwa okufanele kwemimese yomshini, izimo zokugcina, umswakama kanye nokushisa komoya, kanye nokwembozwa okwengeziwe kuzovikela imimese yakho futhi kugcine ukusebenza kwayo kokusika.

Isikhathi sokuthunyelwe: Julayi-18-2025