Embonini yamabhodi ahlanganisiwe, izinhlobo eziningana zemimese zingasetshenziswa ekunqumeni, kodwa ezivame kakhulu nezisebenzayo yilezi:

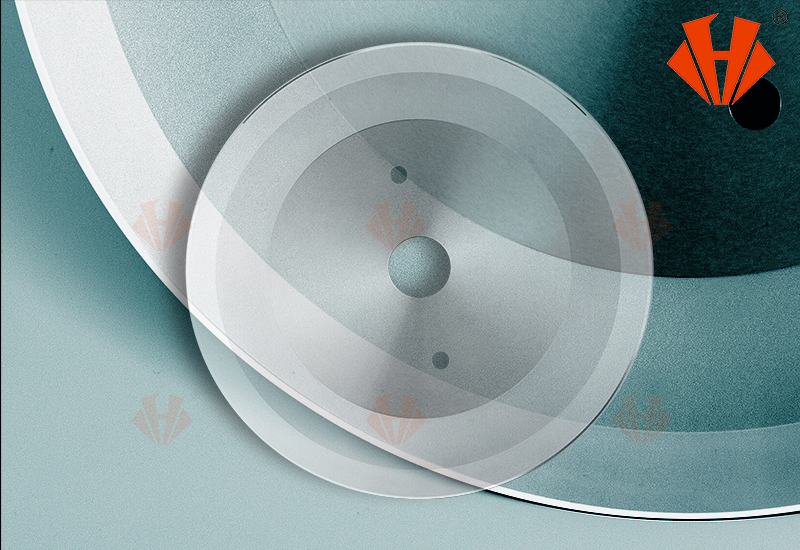

1. Imimese Eyisiyingi Yokusika:

Lezi zithandwa kakhulu ngokunemba kwazo kanye nekhono lokusingatha ukukhiqizwa okusheshayo. Zingancishiswa noma zibe nohlangothi olunezinsika, kuye ngokuthi zinkulu kangakanani izinto kanye nekhwalithi yokusika oyifunayo.

Ama-Circular Blades asetshenziswa kakhulu ekusikeni kwezimboni, uma esetshenziswa ekusikeni kwekhadibhodi elihlanganisiwe, kudinga ama-tungsten carbide blades ukubhekana nalezo zinselele, njengokuguga okusheshayo, izinkinga zokusika ikhwalithi, izinkinga zokuhambisana nenqubo, izinkinga zemishini nokufakwa, izinselele zemvelo nezindleko...

2. Imimese Enomphetho Ogobile:

Isetshenziselwa izinto ezijiyile noma uma kudingeka ukusika okuhlanzekile nokubukhali. Zingangena zijule kakhulu ezintweni.

3. Imimese Yomphetho We-Razor:

Kuhle kakhulu ngezinto ezincane, okunikeza ukusika okuhle kakhulu okunengcindezi encane

4. Imimese Yokusika Izinwele:

Ngokuvamile kusetshenziselwa amabhodi asindayo noma anezingqimba eziningi lapho isenzo sokusika sinikeza ukusika okuhlanzekile.

5. Amaphuzu Imimese:

Ngokukhethekile ngokulinganisa, okubalulekile ngaphambi kokugoqa amabhodi anezinti, nakuba kungenjalo ngqo ngokuhlukanisa.

Ukukhetha ama-Tungsten Carbide Circular Blades:

Uma ukhetha ama-blade ayindilinga e-tungsten carbide okusika ibhodi eligoqiwe, kufanele kucatshangelwe izici eziningana:

Ukuqina Kwezinto Ezibonakalayo:

I-Tungsten Carbide: Yaziwa ngokuqina kwayo okukhulu, igcina ubukhali isikhathi eside kunensimbi, inciphisa isikhathi sokungasebenzi kokushintsha ama-blade nokulola kabusha. Kodwa-ke, iyaphuka, ngakho-ke ukuphathwa ngokucophelela kuyadingeka.

Ijiyometri yeBlade:

I-Edge Angle: I-engeli encane (ebukhali kakhulu) izonikeza ukusika okubukhali kodwa ingase iguge ngokushesha. I-engeli enkulu (efiphele kakhulu) inikeza ukuqina kodwa ingase ingasiki kahle.

Ububanzi kanye Nobukhulu: Lokhu kumele kuhambisane nemininingwane yomshini wokusika kanye nobukhulu bebhodi elihlanganisiwe ukuqinisekisa ukuthi ingcindezi yokusika iyalingana.

Ikhwalithi Yomphetho:

Ukuqeda Okungaphezulu: Unqenqema olucwebezelisiwe lunciphisa ukungqubuzana, okuholela ekusikeni okubushelelezi kanye nokukhiqizwa okuncane kothuli.

I-Burr-Free: Iqinisekisa ukuthi i-blade iyasikwa ngaphandle kokudabula iphepha.

Ukuqina Nokumelana Nokugqokwa:

Cabanga ngobude besikhathi obulindelekile be-blade ngaphansi kwezimo zakho zokusebenza ezithile. Ukumelana nokuguguleka kwe-tungsten carbide kuyinzuzo enkulu, kodwa uhlobo lwe-carbide (isb., ene-cobalt noma engenayo) lungathinta lokhu.

Izidingo Ezikhethekile Zohlelo Lokusebenza:

Isivinini Sokusika: Isivinini esiphezulu singadinga ama-blade anokumelana nokushisa okuthuthukisiwe noma izindlela zokupholisa ukuvimbela ukwanda kokushisa.

Uhlobo Lwezinto: Amabhodi ahlukene ahlanganisiwe (udonga olulodwa, oluphindwe kabili, noma oluthathu) angadinga ukulungiswa ekukhetheni ama-blade.

Izindleko vs. Ukusebenza:

Nakuba i-tungsten carbide ibiza kakhulu kunensimbi, ukuhlala kwayo isikhathi eside kanye nokusebenza kwayo kungase kuthethelele izindleko, ikakhulukazi ezimweni zokukhiqiza ngobuningi obukhulu.

Ukuphepha Nokufakwa:

Qinisekisa ukuthi ama-blade ayahambisana nemishini yakho maqondana nezici zokufaka kanye zokuphepha. Ukufakwa kahle kubalulekile ukuze ugweme ukushelela noma ukulimala kwama-blade.

Ukulola kabusha:

Nakuba ama-blade e-tungsten carbide ehlala isikhathi eside, angalolwa kabusha, kodwa le nsizakalo ingaba ekhethekile futhi ibize kakhulu uma iqhathaniswa nama-blade ensimbi.

Izimo Zemvelo:

Cabanga ngendawo yokusebenza; isibonelo, umswakama noma uthuli kungathinta ukusebenza kwe-blade ngokuhamba kwesikhathi.

Ngokuhlola lezi zici, ungakhetha ama-tungsten carbide circular blades anikeza ibhalansi engcono kakhulu phakathi kwekhwalithi yokusika, ukuqina, kanye nezidingo zokugcinwa kwemisebenzi yakho yokusika amabhodi anezinti.

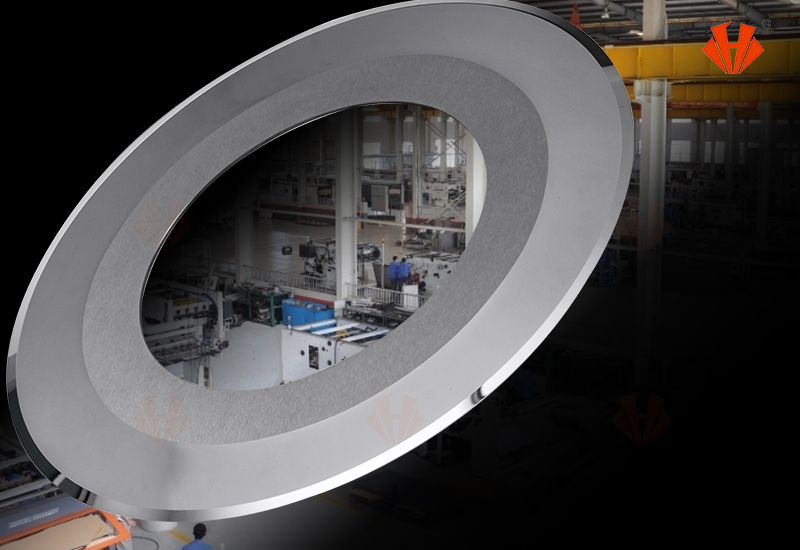

Mayelana neHuaxin: Umkhiqizi Wemimese Yokusika Ene-Cemented Tungsten Carbide

I-CHENGDU HUAXIN CEMENTED CARBIDE CO., LTD ingumhlinzeki ochwepheshe kanye nomkhiqizi wemikhiqizo ye-tungsten carbide, njengemimese yokufaka i-carbide yokwenza ukhuni, imimese eyindilinga ye-carbide yokusika izinduku zokuhlunga ugwayi nogwayi, imimese eyindilinga yokusika amakhadibhodi anezimbobo ezintathu, ama-razor blades/ama-slotted blades okupakisha, i-tape, ukusika ifilimu encane, ama-fiber cutter blades embonini yezindwangu njll.

Njengoba sekuyiminyaka engaphezu kwengu-25 sithuthukisa imikhiqizo yethu, ithunyelwe kwamanye amazwe e-US A, Russia, South America, India, Turkey, Pakistan, Australia, Southeast Asia njll. Ngekhwalithi enhle kakhulu namanani ancintisanayo, isimo sethu sengqondo sokusebenza kanzima kanye nokuphendula kuyavunyelwa amakhasimende ethu. Futhi singathanda ukwakha ubudlelwano obusha bebhizinisi namakhasimende amasha.

Xhumana nathi namuhla futhi uzojabulela izinzuzo zekhwalithi enhle kanye nezinsizakalo ezivela emikhiqizweni yethu!

Imikhiqizo yezimboni ze-tungsten carbide esebenza kahle kakhulu

Isevisi Yangokwezifiso

I-Huaxin Cemented Carbide ikhiqiza ama-blade e-tungsten carbide enziwe ngokwezifiso, ama-blank ashintshiwe ajwayelekile najwayelekile kanye nama-preform, kusukela ku-powder kuya kuma-blank aqediwe. Ukukhetha kwethu okuphelele kwama-grade kanye nenqubo yethu yokukhiqiza kunikeza njalo amathuluzi asebenza kahle kakhulu, athembekile acishe abe yi-net abhekana nezinselele ezikhethekile zokusetshenziswa kwamakhasimende kuzo zonke izimboni ezahlukahlukene.

Izixazululo Ezilungiselelwe Yonke Imboni

ama-blade aklanywe ngokwezifiso

Umkhiqizi ohamba phambili wama-blade ezimboni

Imibuzo evamile yamakhasimende kanye nezimpendulo ze-Huaxin

Lokho kuncike enanini, ngokuvamile izinsuku ezi-5-14. Njengomkhiqizi wezinsika zezimboni, i-Huaxin Cement Carbide ihlela ukukhiqizwa ngama-oda kanye nezicelo zamakhasimende.

Ngokuvamile amasonto ama-3-6, uma ucela imimese yomshini eyenziwe ngokwezifiso noma ama-blade ezimboni angekho esitokweni ngesikhathi sokuthenga. Thola i-Sollex Purchase & Delivery Conditions lapha.

uma ucela imimese yomshini eyenziwe ngokwezifiso noma ama-blade ezimboni angekho esitokweni ngesikhathi sokuthenga. Thola Izimo Zokuthenga Nokulethwa ze-Sollexlapha.

Ngokuvamile i-T/T, i-Western Union...idiphozithi kuqala, Wonke ama-oda okuqala avela kumakhasimende amasha akhokhelwa kusengaphambili. Ama-oda engeziwe angakhokhwa nge-invoyisi...Xhumana nathiukwazi okwengeziwe

Yebo, xhumana nathi, imimese yezimboni iyatholakala ngezindlela ezahlukene, kufaka phakathi imimese enesitsha esiphezulu, imimese eyindilinga engezansi, imimese enezinyo ezigobile/ezinamazinyo, imimese ebhoboza nxazonke, imimese eqondile, imimese ye-guillotine, imimese ecijile, imimese ye-razor engunxande, kanye nemimese ye-trapezoidal.

Ukuze sikusize uthole i-blade engcono kakhulu, i-Huaxin Cement Carbide ingakunikeza ama-blade amaningana amasampula ongawahlola ekukhiqizweni. Ukuze usike futhi uguqule izinto eziguquguqukayo njengefilimu yepulasitiki, i-foil, i-vinyl, iphepha, nokunye, sinikeza ama-blade okuguqula kufaka phakathi ama-slitter blade anezikhala kanye nama-razor blade anezikhala ezintathu. Sithumelele umbuzo uma unentshisekelo kuma-blade omshini, futhi sizokunikeza isipho. Amasampula emimese eyenziwe ngokwezifiso awatholakali kodwa wamukelekile uku-oda inani elincane kakhulu le-oda.

Kunezindlela eziningi ezizokwandisa isikhathi eside kanye nokuphila kweshelufu kwemimese yakho yezimboni kanye nama-blade esitokweni. Xhumana nathi ukuze wazi ukuthi ukupakishwa okufanele kwemimese yomshini, izimo zokugcina, umswakama kanye nokushisa komoya, kanye nokwembozwa okwengeziwe kuzovikela imimese yakho futhi kugcine ukusebenza kwayo kokusika.

Isikhathi sokuthunyelwe: Okthoba-10-2025