Zenziwa kanjani izingcezu ze-carbide?

Ama-carbide blades ayaziswa ngenxa yokuqina kwawo okungavamile, ukumelana nokuguguleka, kanye nekhono lokugcina ubukhali isikhathi eside, okwenza abe afaneleka kakhulu ekusikeni izinto eziqinile.

Ama-carbide blades ngokuvamile enziwa kusetshenziswa inqubo ehilela ukucwilisa i-tungsten carbide powder ibe yisimo esiqinile, kulandelwe ukubumba nokuqedela i-blade. Nasi isifinyezo sesinyathelo ngesinyathelo sendlela ama-carbide blades akhiqizwa ngayo ngokuvamile:

1. Ukulungiselela Izinto Ezingavuthiwe

- I-Tungsten CarbideImpuphu: Izinto eziyinhloko ezisetshenziswa kuma-carbide blades yi-tungsten carbide (WC), okuyinhlanganisela eqinile neqinile ye-tungsten ne-carbon. Uhlobo lwempuphu ye-tungsten carbide luxutshwa nensimbi yokubopha, ngokuvamile i-cobalt (Co), ukusiza ngenqubo yokuhlanza.

- Ukuxuba Ufulawa: Impuphu ye-tungsten carbide kanye ne-cobalt kuhlanganiswa ndawonye ukuze kwakhiwe ingxube efanayo. Ingxube ilawulwa ngokucophelela ukuqinisekisa ukwakheka okufanele kokuqina nokuqina kwe-blade oyifunayo.

2. Ukucindezela

- Ukubumba: Ingxube yempuphu ifakwa ku-mold noma ku-diye bese icindezelwa ibe yisimo esiqinile, okuyisimo esimaphakathi se-blade. Lokhu kuvame ukwenziwa ngaphansi kwengcindezi ephezulu enqubweni ebizwa ngokuthiukucindezela okubandayo kwe-isostatic (CIP) or ukucindezela okukodwa.

- Ukubumba: Ngesikhathi sokucindezela, isimo se-blade siyakheka, kodwa asikaqini ngokugcwele noma asikaqini. Ukucindezela kusiza ukuhlanganisa ingxube ye-powder ibe yi-geometry oyifunayo, njengesimo sethuluzi lokusika noma i-blade.

3. Ukuhlanza

- Ukushisa Okuphezulu Kokushisa: Ngemva kokucindezela, i-blade idlula enkambisweni yokusha. Lokhu kuhilela ukushisa isimo esicindezelwe esithandweni somlilo emazingeni okushisa ngokuvamile phakathi1,400°C kanye no-1,600°C(2552°F kuya ku-2912°F), okubangela ukuthi izinhlayiya zempuphu zihlangane futhi zakhe into eqinile, eqinile.

- Ukususwa Kwe-Binder: Ngesikhathi sokusila, i-cobalt binder nayo iyacutshungulwa. Isiza izinhlayiya ze-tungsten carbide ukuthi zinamathele komunye nomunye, kodwa ngemva kokusila, futhi iyasiza ukunikeza i-blade ubulukhuni bayo bokugcina kanye nokuqina.

- Ukupholisa: Ngemva kokusha, i-blade ipholiswa kancane kancane endaweni elawulwayo ukuze kugwenywe ukuqhekeka noma ukuphambuka.

4. Ukugaya Nokubumba

- Ukugaya: Ngemva kokusha, i-carbide blade ivame ukuba lukhuni kakhulu noma ingajwayelekile, ngakho-ke iyagaywa ibe nobukhulu obuqondile kusetshenziswa amasondo akhethekile okuhudula noma imishini yokugaya. Lesi sinyathelo sibalulekile ekudaleni unqenqema olubukhali nokuqinisekisa ukuthi i-blade ihlangabezana nemigomo edingekayo.

- Ukubumba Nokuphrofayilisha: Kuye ngokuthi isetshenziswa kanjani, i-blade ingase iqhubeke nokuma noma ukuphrofayilisha. Lokhu kungabandakanya ukugaya ama-engeli athile onqenqemeni lokusika, ukufaka izembozo, noma ukulungisa kahle i-geometry iyonke ye-blade.

5. Ukwelashwa Kokuqeda

- Ukugqoka Okungaphezulu (Ongakukhetha): Amanye ama-carbide blades athola ukwelashwa okwengeziwe, njengokumbozwa kwezinto ezifana ne-titanium nitride (TiN), ukuze kuthuthukiswe ubulukhuni, ukumelana nokuguguleka, futhi kuncishiswe ukungqubuzana.

- Ukupholisha: Ukuze kuthuthukiswe ukusebenza, i-blade ingapholishwa ukuze kufezwe indawo ebushelelezi, eqediwe enciphisa ukungqubuzana futhi ithuthukise ukusebenza kahle kokusika.

6. Ukulawulwa Kwekhwalithi Nokuhlolwa

- Ukuhlolwa Kokuqina: Ubulukhuni be-blade buvame ukuhlolwa ukuqinisekisa ukuthi buhlangabezana nezimfuneko ezidingekayo, ngokuhlolwa okuvamile okuhlanganisa nokuhlolwa kobulukhuni be-Rockwell noma i-Vickers.

- Ukuhlolwa Kobukhulu: Ukunemba kubalulekile, ngakho-ke ubukhulu be-blade buyahlolwa ukuqinisekisa ukuthi buhlangabezana nokubekezelelana okuqondile.

- Ukuhlolwa Kokusebenza: Ngezinhlelo zokusebenza ezithile, njengokusika noma ukunquma, i-blade ingase ihlolwe emhlabeni wangempela ukuqinisekisa ukuthi isebenza njengoba kuhlosiwe.

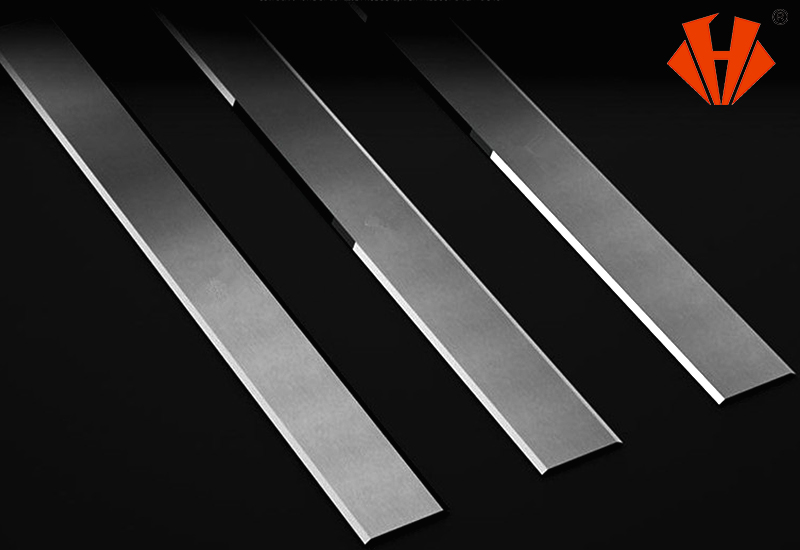

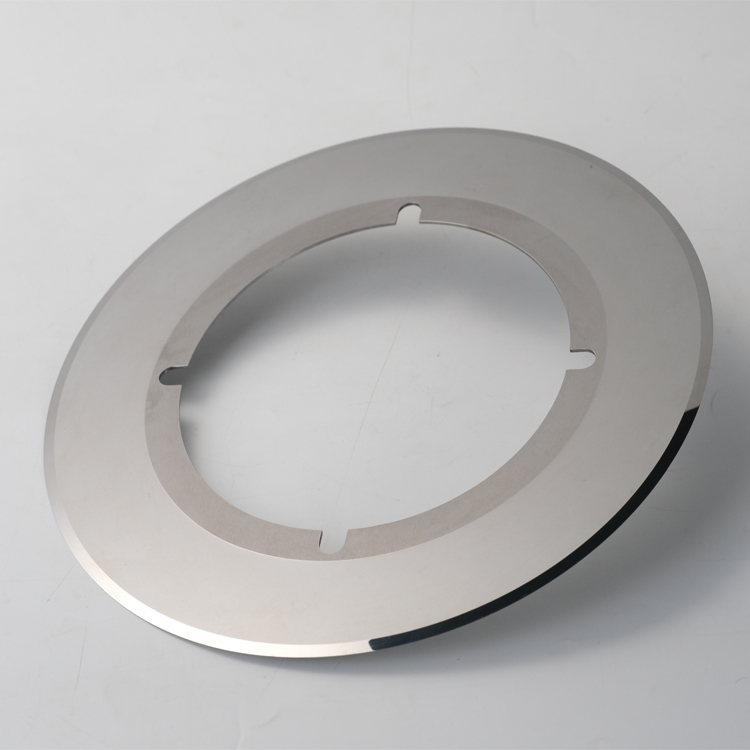

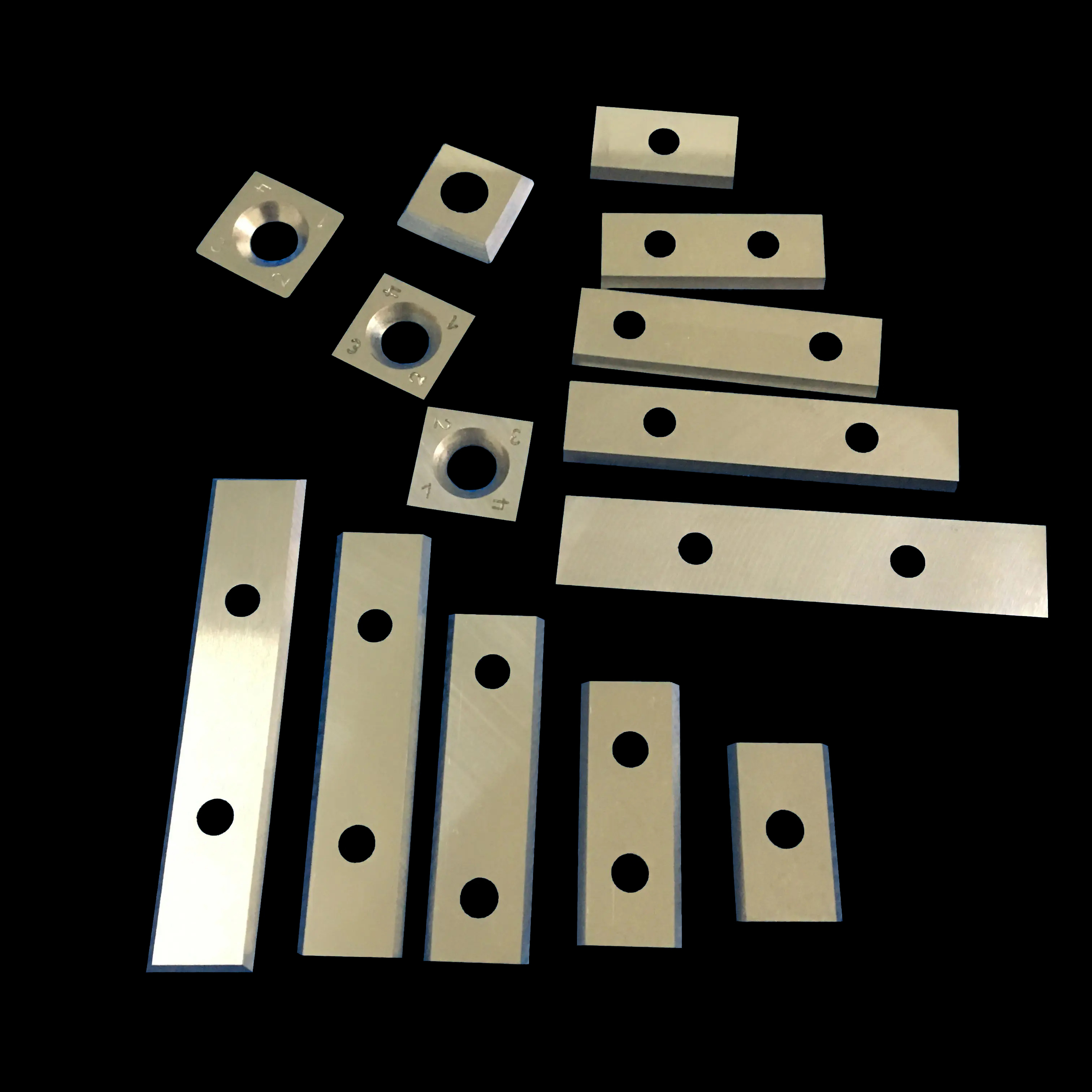

I-HUAXIN CERMENTED CARBIDE inikeza imimese ye-tungsten carbide kanye nama-blade asezingeni eliphezulu kumakhasimende ethu avela ezimbonini ezahlukene emhlabeni jikelele. Ama-blade angalungiswa ukuze afane nemishini esetshenziswa cishe kunoma yiluphi uhlelo lokusebenza lwezimboni. Izinto ze-blade, ubude bomphetho kanye namaphrofayili, ukwelashwa kanye nokugqoka kungashintshwa ukuze kusetshenziswe nezinto eziningi zezimboni.

Uma ama-blade esedlulile kuzo zonke izivivinyo zekhwalithi, asuke eselungele ukusetshenziswa ezinhlotsheni ezahlukene zezimboni, njengasekusebenzeni ngensimbi, ekupakisheni, noma kweminye imisebenzi yokusika lapho ukumelana nokuguguleka okuphezulu kanye nobukhali kubalulekile khona.

Isikhathi sokuthunyelwe: Novemba-25-2024