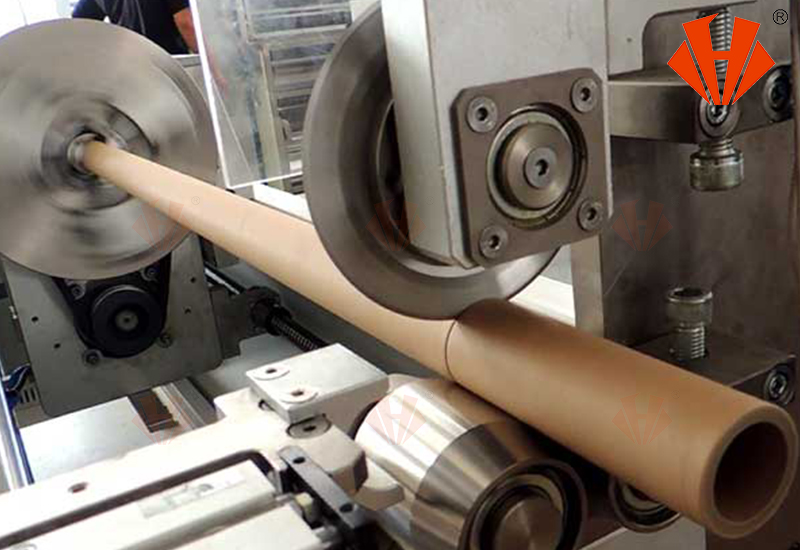

Ukunemba nokuqina kubaluleke kakhulu ekufinyeleleni ukusika okusebenzayo, embonini yokucubungula amaphepha, okuseqophelweni eliphezulu. Ama-blade e-tungsten carbide ezimboni asezingeni eliphezulu asetshenziswa kabanzi emishinini yokusika amaphepha ngenxa yokuqina kwawo okuphezulu, isikhathi eside, kanye nekhono lokuletha ukusika okuhlanzekile nokunembile emijikelezweni emide yokukhiqiza. Lawa ma-blade, aziwa ngokuthiama-blade okusika i-tungsten carbide,ama-blade ensimbi ye-tungstennomaama-razor blades e-tungsten, inikeza izinzuzo ezibalulekile ezithuthukisa ukusebenza kwezicelo zokusika amaphepha.

Kungani Ama-Tungsten Carbide Blades Ebalulekile Ekusikeni Iphepha

Imishini yokusika amaphepha kumele icubungule inani elikhulu lephepha ngezinga eliphezulu lokunemba, ngokuvamile ngesivinini esikhulu. Ukuze kuhlangatshezwane nalezi zidingo, imboni ithembela kakhulu kuma-tungsten carbide blades ngenxa yezakhiwo zayo eziyingqayizivele:

Ukuqina Nokuqina Okungenakuqhathaniswa

I-Tungsten carbideingenye yezinto ezilukhuni kakhulu ezitholakalayo, okwenza imelane kakhulu nokuguguleka nokuklwebheka. Emishinini yokusika amaphepha, lapho ama-blade ehlala evezwa ukungqubuzana futhi kumele abekezelele ukunqunywa okuphindaphindiwe, ukuqina okuphezulu kwama-blade e-tungsten carbide kunciphisa imvamisa yokufakwa esikhundleni. Lokhu kuqina kubaluleke kakhulu ekucutshungulweni kwamaphepha amaningi lapho kudingeka khona ukusebenza okuqhubekayo ukuze kulondolozwe umkhiqizo.

Ukugcinwa Okuphezulu Komphetho Nokukhalipha

Ama-blade ensimbi ye-tungsten aziwa ngokucija kwawo okuhlala isikhathi eside, okuqinisekisa ukuthi ukusika ngakunye kuhlanzekile futhi kunembe njengokugcina. Ngokungafani nama-blade ensimbi avamile, angafiphala ngokushesha, ama-blade e-tungsten carbide agcina umkhawulo obukhali uma esetshenziswa isikhathi eside, okuholela ekunembeni okuphezulu ekusikeni. Emishinini yokusika amaphepha, lokhu kunciphisa ukumosheka okubangelwa imiphetho engalingani noma eqhekekile, ngenkathi kuthuthukiswa ikhwalithi yomkhiqizo iyonke.

Ukumelana Okuphezulu Nokugqwala Nomthelela

Ezindaweni zokusika amaphepha, ama-blade angavezwa umswakama, uyinki, kanye nezinye izinto ezingcolisayo. Ukumelana kwe-tungsten carbide nokugqwala kusiza ukugcina ikhwalithi yama-blade, ukuqinisekisa ukuthi ahlala esebenza kahle ngisho nasezimweni ezinzima. Ngaphezu kwalokho, ukumelana okuphezulu kwe-tungsten carbide kuvumela la ma-blade ukuthi abhekane nokusikeka okungazelelwe, okunomfutho ophezulu ngaphandle kokuqhekeka noma ukuphuka, okuwusizo kakhulu ekusetshenzisweni kwephepha lezimboni.

Ukusebenza kahle kwezicelo zesivinini esiphezulu kanye nevolumu ephezulu

Ikhono le-tungsten carbide lokubekezelela ukushisa nokumelana nokuguquka kwenza kube ukukhetha okuhle kakhulu kokusebenza okusheshayo, lapho ukungqubuzana kanye nokukhiqizwa kokushisa kuhlala njalo. Ukushisa kwe-tungsten carbide kusiza ukuqeda ukushisa, kuvimbele i-blade ekushiseni ngokweqile, okubaluleke kakhulu emishinini yokusika iphepha eqhubekayo. Lokhu kumelana nokushisa kuthuthukisa nokuzinza kwe-blade kanye nokuphila kwayo, okufaka isandla ekusebenzeni kahle okuphelele.

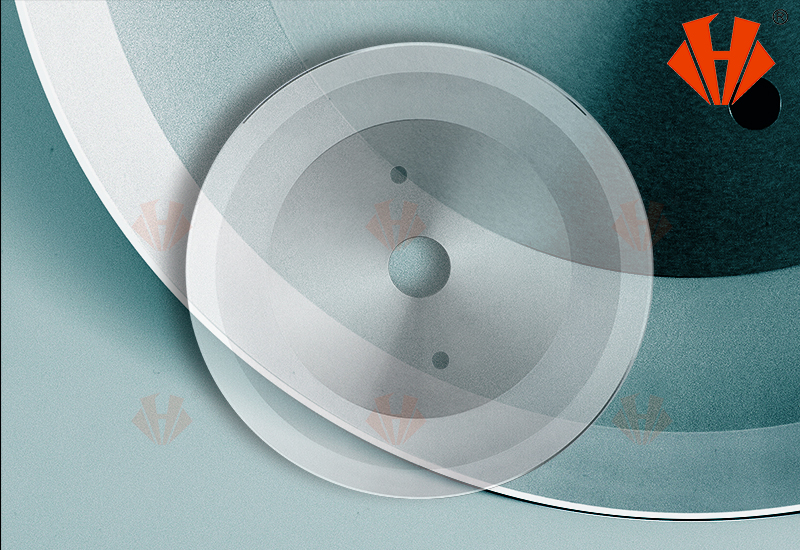

Izinhlobo ze-Tungsten Carbide Blades zokuSika Iphepha

Ekusetshenzisweni kokusika amaphepha, izinhlobo ezahlukene zama-tungsten carbide blades zenzelwe ukuhlangabezana nezidingo ezahlukene zokusika:

- Ama-blade Okusika I-Tungsten Carbide

Lezi zinsika eziguquguqukayo zivame ukusetshenziselwa ukusika ngenhloso evamile ekucutshungulweni kwephepha. Zifanele izinhlobo eziningi zephepha, kusukela kumashidi ajwayelekile kuya esitokweni esinzima, okunikeza ukusebenza okulinganayo ezintweni ezahlukahlukene. - Ama-Blades ensimbi e-Tungsten

Aziwa ngokuqina kwawo, ama-blade ensimbi ye-tungsten asetshenziselwa imisebenzi edinga ukuqina okuphezulu, njengokusika amavolumu amakhulu ephepha noma izinhlobo zephepha ezisindayo. Lawa ma-blade amelana kakhulu nokuguqulwa nokufiphala, okwenza afaneleke kakhulu ekusetshenzisweni okufunwa kakhulu ekunyathelisweni kwezentengiselwano nasekukhiqizweni kwephepha. - Ama-Blade e-Tungsten Razor

Njengoba zibukhali njenge-razor yendabuko, ama-razor blade e-tungsten afaneleka kakhulu emisebenzini yokunemba edinga ukusikwa okuncane kakhulu. Lawa ma-blade avame ukusetshenziswa ezinhlotsheni lapho ukunemba kanye nekhwalithi yomphetho kubalulekile khona, njengasekusikeni amaphepha akhethekile noma ezinhlotsheni ezidinga ukusikwa okunembe kakhulu.

Ukukhetha i-Tungsten Carbide Blade Efanele Yemishini Yokusika Iphepha

Uma ukhetha i-tungsten carbide blade yomshini wokusika iphepha, kubalulekile ukucabangela izici ezifana nohlobo lwephepha, umthamo wokukhiqiza, kanye nesivinini sokusebenza komshini. Ama-tungsten carbide blade asezingeni eliphezulu aklanyelwe amamodeli athile omshini nezidingo zezinto ezibonakalayo avame ukutholakala kubakhiqizi abaphambili, abanikeza izinketho ezenziwe ngokwezifiso zokukhulisa umkhiqizo kanye nokuphila kwe-blade. Ukukhetha i-blade efanele kunganciphisa kakhulu isikhathi sokungasebenzi futhi kuthuthukise ikhwalithi yomkhiqizo ngokuletha ukusika okuqhubekayo nokubushelelezi.

Ama-blade okusika i-tungsten carbide asezingeni eliphezulu, ama-blade ensimbi ye-tungsten, kanye nama-razor blade e-tungsten abe yinto ebalulekile emishinini yokusika amaphepha ngenxa yokuqina kwawo, ubukhali, kanye nokumelana nezimo zezimboni ezinzima. Lawa ma-blade asiza ukugcina umkhiqizo ezindaweni zokucubungula amaphepha ezinomthamo ophezulu, ezisheshayo ngokuletha ukusika okunembile nokuthembekile esikhathini eside. Ezinkampanini embonini yokucubungula amaphepha, ukutshala imali kuma-blade e-tungsten carbide kuyindlela engabizi kakhulu yokufeza ikhwalithi yomkhiqizo engcono, isikhathi esincane sokungasebenzi, kanye nokuthuthukiswa okuphelele ekusebenzeni kahle kokusika.

Mayelana neHuaxin: Umkhiqizi Wemimese Yokusika Ene-Cemented Tungsten Carbide

I-CHENGDU HUAXIN CEMENTED CARBIDE CO., LTD ingumhlinzeki ochwepheshe kanye nomkhiqizi wemikhiqizo ye-tungsten carbide, njengemimese yokufaka i-carbide yokwenza ukhuni, imimese eyindilinga ye-carbide yokusika izinduku zokuhlunga ugwayi nogwayi, imimese eyindilinga yokusika amakhadibhodi anezimbobo ezintathu, ama-razor blades/ama-slotted blades okupakisha, i-tape, ukusika ifilimu encane, ama-fiber cutter blades embonini yezindwangu njll.

Njengoba sekuyiminyaka engaphezu kwengu-25 sithuthukisa imikhiqizo yethu, ithunyelwe kwamanye amazwe e-US A, Russia, South America, India, Turkey, Pakistan, Australia, Southeast Asia njll. Ngekhwalithi enhle kakhulu namanani ancintisanayo, isimo sethu sengqondo sokusebenza kanzima kanye nokuphendula kuyavunyelwa amakhasimende ethu. Futhi singathanda ukwakha ubudlelwano obusha bebhizinisi namakhasimende amasha.

Xhumana nathi namuhla futhi uzojabulela izinzuzo zekhwalithi enhle kanye nezinsizakalo ezivela emikhiqizweni yethu!

Imikhiqizo yezimboni ze-tungsten carbide esebenza kahle kakhulu

Isevisi Yangokwezifiso

I-Huaxin Cemented Carbide ikhiqiza ama-blade e-tungsten carbide enziwe ngokwezifiso, ama-blank ashintshiwe ajwayelekile najwayelekile kanye nama-preform, kusukela ku-powder kuya kuma-blank aqediwe. Ukukhetha kwethu okuphelele kwama-grade kanye nenqubo yethu yokukhiqiza kunikeza njalo amathuluzi asebenza kahle kakhulu, athembekile acishe abe yi-net abhekana nezinselele ezikhethekile zokusetshenziswa kwamakhasimende kuzo zonke izimboni ezahlukahlukene.

Izixazululo Ezilungiselelwe Yonke Imboni

ama-blade aklanywe ngokwezifiso

Umkhiqizi ohamba phambili wama-blade ezimboni

Imibuzo evamile yamakhasimende kanye nezimpendulo ze-Huaxin

Lokho kuncike enanini, ngokuvamile izinsuku ezi-5-14. Njengomkhiqizi wezinsika zezimboni, i-Huaxin Cement Carbide ihlela ukukhiqizwa ngama-oda kanye nezicelo zamakhasimende.

Ngokuvamile amasonto ama-3-6, uma ucela imimese yomshini eyenziwe ngokwezifiso noma ama-blade ezimboni angekho esitokweni ngesikhathi sokuthenga. Thola i-Sollex Purchase & Delivery Conditions lapha.

uma ucela imimese yomshini eyenziwe ngokwezifiso noma ama-blade ezimboni angekho esitokweni ngesikhathi sokuthenga. Thola Izimo Zokuthenga Nokulethwa ze-Sollexlapha.

Ngokuvamile i-T/T, i-Western Union...idiphozithi kuqala, Wonke ama-oda okuqala avela kumakhasimende amasha akhokhelwa kusengaphambili. Ama-oda engeziwe angakhokhwa nge-invoyisi...Xhumana nathiukwazi okwengeziwe

Yebo, xhumana nathi, imimese yezimboni iyatholakala ngezindlela ezahlukene, kufaka phakathi imimese enesitsha esiphezulu, imimese eyindilinga engezansi, imimese enezinyo ezigobile/ezinamazinyo, imimese ebhoboza nxazonke, imimese eqondile, imimese ye-guillotine, imimese ecijile, imimese ye-razor engunxande, kanye nemimese ye-trapezoidal.

Ukuze sikusize uthole i-blade engcono kakhulu, i-Huaxin Cement Carbide ingakunikeza ama-blade amaningana amasampula ongawahlola ekukhiqizweni. Ukuze usike futhi uguqule izinto eziguquguqukayo njengefilimu yepulasitiki, i-foil, i-vinyl, iphepha, nokunye, sinikeza ama-blade okuguqula kufaka phakathi ama-slitter blade anezikhala kanye nama-razor blade anezikhala ezintathu. Sithumelele umbuzo uma unentshisekelo kuma-blade omshini, futhi sizokunikeza isipho. Amasampula emimese eyenziwe ngokwezifiso awatholakali kodwa wamukelekile uku-oda inani elincane kakhulu le-oda.

Kunezindlela eziningi ezizokwandisa isikhathi eside kanye nokuphila kweshelufu kwemimese yakho yezimboni kanye nama-blade esitokweni. Xhumana nathi ukuze wazi ukuthi ukupakishwa okufanele kwemimese yomshini, izimo zokugcina, umswakama kanye nokushisa komoya, kanye nokwembozwa okwengeziwe kuzovikela imimese yakho futhi kugcine ukusebenza kwayo kokusika.

Isikhathi sokuthunyelwe: Agasti-27-2025