Ama-blade okusika e-tungsten carbide asetshenziswa kabanzi embonini yamakhadibhodi ahlanganisiwe ngenxa yobunzima bawo kanye nokumelana nokuguguleka. Kodwa-ke, ngesikhathi senqubo yokusika, lawa ma-blade asengalimala, okuholela ekusebenzeni okunciphile, isikhathi sokungasebenzi esandisiwe, kanye nezindleko zokusebenza eziphakeme. Ukuqonda izimbangela ezivamile zokulimala kwama-blade nokusebenzisa ukuthuthukiswa okuqondiwe kubalulekile ekwenzeni ngcono inqubo yokusika. Ngezansi, ngichaza izizathu eziyinhloko zokulimala kwama-blade kanye namasu ahambisanayo okuthuthukisa ama-blade.

Izizathu Zokulimala Kwe-Tungsten Carbide Slitting Blade

●Ukugqoka Okungagugi

Ikhadibhodi elinongwengwezi, ikakhulukazi uma lenziwe ngemicu ephinde yasetshenziswa noma equkethe okuqukethwe amaminerali (isb., izigcwalisi noma izembozo), lingaba nokukhuhla kakhulu. Lokhu kukhuhla kubangela ukuthi unqenqema lwe-blade luguge ngokuhamba kwesikhathi, okuholela ekubeni buthuntu futhi kunciphise ukusebenza kahle kokusika.

●Ukwakheka Okunamathelayo

Izinamathiseli ezisetshenziswa ekufakweni kwezendlalelo zekhadibhodi ezihlanganisiwe zinganamathela ensikeni ngesikhathi sokusika. Lokhu kwakheka kuthinta ubukhali bensika, kwandisa ukungqubuzana, futhi kungabangela ukuthi insika ishise ngokweqile noma iphuke ngisho nalapho icindezelekile.

●Ukufakwa Kwe-Blade Okungafanele

Uma i-blade ingalungiswanga kahle noma ingafakwanga kahle emshinini wokusika, ingase iguge ngokungalingani noma iphuke ngokuzumayo. Ukungalungi kahle kungaholela nasekudlidlizeni ngokweqile, okusheshisa umonakalo.

●Amandla Okusika Adlulele

Ukusebenzisa amandla amaningi ngesikhathi senqubo yokusika, ikakhulukazi lapho usika ikhadibhodi eliqinile noma eliqinile, kungabangela ukuthi i-blade iqhekezeke noma iqhekeke. Lokhu kuyinkinga ikakhulukazi uma i-blade ihlangana nokushintshashintsha kwezinto okungalindelekile, njengamafindo noma izindawo ezixineneyo ekhadibhodini.

●Ukukhiqiza Ukushisa

Ukungqubuzana phakathi kwe-blade nekhadibhodi kudala ukushisa, okungathambisa izinto ze-tungsten carbide, okuholela ekugugeni ngaphambi kwesikhathi, ekuguqukeni, noma ngisho nasekuqhekekeni kokushisa. Ukushisa okweqile nakho kwenza kube kubi kakhulu ukwakheka kwe-glue.

●Ukungahambisani Kwezinto Ezibonakalayo

Ukwehluka kobukhulu, ubuningi, noma ukwakheka kwekhadibhodi (isb., okuqukethwe umswakama noma ukuma kwefayibha) kungadala ukucindezeleka okungalindelekile ebheleni. Lokhu kungahambisani kungabangela ukuthi ibheli libhekane nokushayisana okungazelelwe noma umthwalo ongalingani, okuholela ekuqhekekeni noma ekuqhekekeni.

Amasu Okuthuthukisa Ama-Blade

Ukuze kuxazululwe izinkinga ezishiwo ngenhla futhi kuthuthukiswe ukuqina nokusebenza kahle kwama-blade okunqamula e-tungsten carbide, kungasetshenziswa amasu alandelayo:

●●● Ukuthuthukiswa Kwezinto Ezibonakalayo

Sebenzisa izinga eliphezulu le-tungsten carbide enezakhiwo zokusanhlamvu ezicolekile noma ufake izithasiselo (isb., ama-cobalt binders noma amanye ama-carbides) ukuze wandise ubulukhuni be-blade, ukuqina kwayo, kanye nokumelana nokuguguleka kwayo. Lokhu kusiza i-blade ukuthi imelane nokuguguleka kwayo futhi kunciphisa imvamisa yokulola noma yokuyishintsha.

●●● Ubuchwepheshe Bokumboza

Faka izembozo ezithuthukisiwe njenge-Titanium Nitride (TiN), i-Titanium Carbonitride (TiCN), noma i-Diamond-Like Carbon (DLC) ebusweni be-blade. Lezi zembozo zinciphisa ukungqubuzana, zithuthukise ukumelana nokuguguleka, futhi zivimbele ukwakheka kwe-glue ngokudala indawo ebushelelezi neqinile emelana nokunamathela nokuguguleka.

●●● Ukuthuthukisa I-Edge Geometry

Lungisa i-geometry ye-blade esezingeni eliphezulu ukuze ivumelane nezici ezithile zekhadibhodi egoqekile. Isibonelo:

Unqenqema olubukhali (isb., olune-radius encane yonqenqema) lungahlinzeka ngokusika okuhlanzekile futhi kunciphise ukudabuka.

Unqenqema oluyindilinga noma olucijile lungasabalalisa amandla okusika ngokulinganayo, okunciphisa ingozi yokuqhekeka lapho kuhlangatshezwana nokungahambisani kwezinto.

Ngaphezu kwalokho, ukwenza ngcono i-engela kanye nephrofayili ye-blade kungathuthukisa ikhono layo lokusingatha isakhiwo se-fluted cardboard egobile ngaphandle kokubambelela.

●●● Ukushabalalisa Ukushisa

Thuthukisa ukwakheka kwe-blade ukuze uthuthukise ukushabalalisa ukushisa ngesikhathi sokusika. Lokhu kungafezwa ngokuthi:

Ukufaka iziteshi zokupholisa noma ukusebenzisa izinto ze-blade ezine-conductivity engcono yokushisa.

Ukuklama i-blade ngendawo enkulu noma ama-heat sink ukuze kuqedwe ukushisa ngempumelelo.

Ukunciphisa ukwakheka kokushisa kusiza ukugcina ubulukhuni be-blade futhi kuvimbele ukulimala kokushisa.

●●●Ikhwalithi yokulawula

Sebenzisa izindlela zokulawula ikhwalithi eziqinile ngesikhathi senqubo yokukhiqiza ukuqinisekisa ukuhambisana kwezakhiwo ze-blade, njengokuqina, ubukhali bomphetho, kanye nokunemba kobukhulu. Lokhu kunciphisa amathuba okuba neziphambeko ezingaholela ekuhlulekeni kwangaphambi kwesikhathi.

●●●Imfundo Yomsebenzisi Nokunakekelwa

Nikeza iziqondiso eziphelele kanye nokuqeqeshwa kokufakwa kwe-blade efanele, ukuqondisa, kanye nokugcinwa kwayo. Ukufundisa abaqhubi ngemingcele efanele yokusika (isb., isivinini, amandla, kanye nokuthambisa) kunganciphisa amaphutha abantu futhi kuvimbele umonakalo obangelwa ukuphathwa kabi.

Ama-blade okusika ama-tungsten carbide asetshenziswa ekusikeni amakhadibhodi anezinti angalimala ngenxa yokuguguleka okunamandla, ukwakheka kwe-sticky, ukufakwa okungafanele, amandla okusika ngokweqile, ukukhiqizwa kokushisa, kanye nokungahambisani kwezinto. Ukuze kuncishiswe lezi zinkinga, ukuthuthukiswa kwama-blade kufanele kugxile ekukhuliseni ukumelana nokuguguleka kwezinto, ukusebenzisa izembozo ezinciphisa ukungqubuzana, ukwenza ngcono i-edge geometry, ukuthuthukisa ukushabalaliswa kokushisa, kanye nokuqinisekisa ukulawulwa kwekhwalithi okuqinile. Ngaphezu kwalokho, ukufundisa abasebenzisi ngokuphathwa nokugcinwa kwama-blade ngendlela efanele kubalulekile ekwandiseni impilo yama-blade nokugcina ukusebenza kahle kokusika. Ngokusebenzisa lawa masu, abakhiqizi banganciphisa kakhulu umonakalo wama-blade, bathuthukise ukuthembeka kokusebenza, futhi banciphise izindleko zokukhiqiza jikelele.

Kungani Ukhethe iChengduhuaxin Carbide?

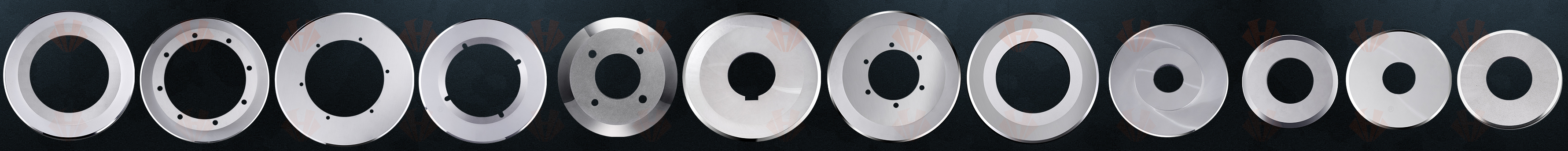

I-Chengduhuaxin Carbide ivelele emakethe ngenxa yokuzibophezela kwayo ekhwalithini nasekusunguleni izinto ezintsha. Ama-blade abo ekhaphethi e-tungsten carbide kanye nama-blade e-tungsten carbide aklanyelwe ukusebenza kahle kakhulu, anikeza abasebenzisi amathuluzi ahlinzeka ngokusika okuhlanzekile nokunembile ngenkathi ebekezelela ubunzima bokusetshenziswa kakhulu kwezimboni. Ngokugxila ekuqineni nasekusebenzeni kahle, ama-blade e-Chengduhuaxin Carbide anikeza ikhambi elifanele izimboni ezidinga amathuluzi okusika anokwethenjelwa.

I-CHENGDU HUAXIN CEMENTED CARBIDE CO.,LTD ingumhlinzeki ochwepheshe kanye nomkhiqizi weimikhiqizo ye-tungsten carbide,njengemimese yokufaka i-carbide yokusebenza ngokhuni, i-carbideimimese eyindilingangobaizinduku zokuhlunga ugwayi nogwayi, imimese eyindilinga ukusika amakhadibhodi ane-corugat,ama-razor blades/ama-slotted blades anezimbobo ezintathu ukupakisha, iteyipu, ukusika ifilimu encane, ama-fiber cutter blades embonini yezindwangu njll.

Njengoba sekuyiminyaka engaphezu kwengu-25 sithuthukisa imikhiqizo yethu, ithunyelwe kwamanye amazwe e-US A, Russia, South America, India, Turkey, Pakistan, Australia, Southeast Asia njll. Ngekhwalithi enhle kakhulu namanani ancintisanayo, isimo sethu sengqondo sokusebenza kanzima kanye nokuphendula kuyavunyelwa amakhasimende ethu. Futhi singathanda ukwakha ubudlelwano obusha bebhizinisi namakhasimende amasha.

Xhumana nathi namuhla futhi uzojabulela izinzuzo zekhwalithi enhle kanye nezinsizakalo ezivela emikhiqizweni yethu!

Imibuzo evamile yamakhasimende kanye nezimpendulo ze-Huaxin

Lokho kuncike enanini, ngokuvamile izinsuku ezi-5-14. Njengomkhiqizi wezinsika zezimboni, i-Huaxin Cement Carbide ihlela ukukhiqizwa ngama-oda kanye nezicelo zamakhasimende.

Ngokuvamile amasonto ama-3-6, uma ucela imimese yomshini eyenziwe ngokwezifiso noma ama-blade ezimboni angekho esitokweni ngesikhathi sokuthenga. Thola i-Sollex Purchase & Delivery Conditions lapha.

uma ucela imimese yomshini eyenziwe ngokwezifiso noma ama-blade ezimboni angekho esitokweni ngesikhathi sokuthenga. Thola Izimo Zokuthenga Nokulethwa ze-Sollexlapha.

Ngokuvamile i-T/T, i-Western Union...idiphozithi kuqala, Wonke ama-oda okuqala avela kumakhasimende amasha akhokhelwa kusengaphambili. Ama-oda engeziwe angakhokhwa nge-invoyisi...Xhumana nathiukwazi okwengeziwe

Yebo, xhumana nathi, imimese yezimboni iyatholakala ngezindlela ezahlukene, kufaka phakathi imimese enesitsha esiphezulu, imimese eyindilinga engezansi, imimese enezinyo ezigobile/ezinamazinyo, imimese ebhoboza nxazonke, imimese eqondile, imimese ye-guillotine, imimese ecijile, imimese ye-razor engunxande, kanye nemimese ye-trapezoidal.

Ukuze sikusize uthole i-blade engcono kakhulu, i-Huaxin Cement Carbide ingakunikeza ama-blade amaningana amasampula ongawahlola ekukhiqizweni. Ukuze usike futhi uguqule izinto eziguquguqukayo njengefilimu yepulasitiki, i-foil, i-vinyl, iphepha, nokunye, sinikeza ama-blade okuguqula kufaka phakathi ama-slitter blade anezikhala kanye nama-razor blade anezikhala ezintathu. Sithumelele umbuzo uma unentshisekelo kuma-blade omshini, futhi sizokunikeza isipho. Amasampula emimese eyenziwe ngokwezifiso awatholakali kodwa wamukelekile uku-oda inani elincane kakhulu le-oda.

Kunezindlela eziningi ezizokwandisa isikhathi eside kanye nokuphila kweshelufu kwemimese yakho yezimboni kanye nama-blade esitokweni. Xhumana nathi ukuze wazi ukuthi ukupakishwa okufanele kwemimese yomshini, izimo zokugcina, umswakama kanye nokushisa komoya, kanye nokwembozwa okwengeziwe kuzovikela imimese yakho futhi kugcine ukusebenza kwayo kokusika.

Isikhathi sokuthunyelwe: Juni-18-2025