Izinselele ziyavela ngesikhathi senqubo yokusika. Uma sibhekene nekhadibhodi elihlanganisiwe eline-grammage ephansi, libonakala ngokuba mncane kwekhadibhodi elihlanganisiwe kanye nokukhanya kwalo...Ngaphezu kwalokho, ama-blade okusika e-tungsten carbide asetshenziswayo kumele ahlangabezane nezidingo ezithile ukuqinisekisa ukusika okuphumelelayo nokunciphisa lezi zinkinga.

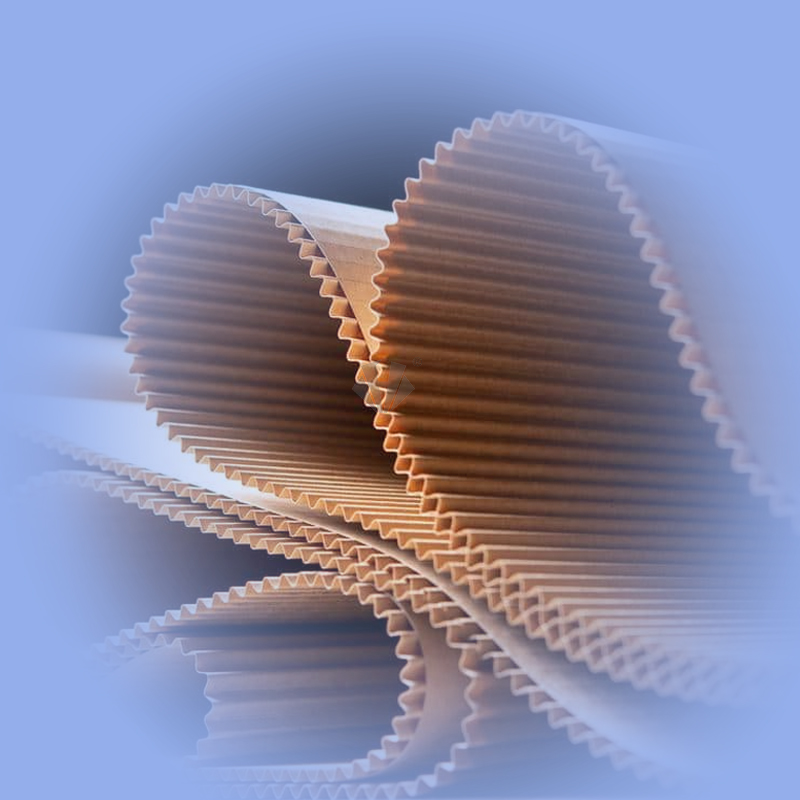

Izinkinga Ezivamile Ngekhadibhodi Eligoqekile Eline-Grammage Eliphansi Elisikayo

● Ukudabuka noma ukuklebhula

Ikhadibhodi eligoqekile eline-grammage ephansi alinamandla okwakheka kwezinhlobo ezijiyile, okwenza lithambekele ekudabukeni kunokuba lithole ukusika okuhlanzekile. Lokhu kungenzeka uma ama-blade engabukhali ngokwanele noma uma kusetshenziswa amandla okusika ngokweqile, okuholela emaphethelweni aqinile noma ezintweni ezonakele.

●I-Blade Dulling

Naphezu kobuncane bayo, ikhadibhodi eligoqekile lingaba yisicaba, ikakhulukazi uma liqukethe imicu esetshenzisiwe noma okuqukethwe amaminerali. Lokhu kusiba yisicaba kubangela ukuthi ama-slitting blades asheshe afiphale, okuholela ekusikeni okungaguquki kanye nezidingo zokunakekelwa ezengeziwe.

●Ukuzikhandla Ngezigubhu

Ingqimba egobile ekhadibhodini eligobile ingabangela ukuthi ama-blade abambe noma abambeke ngesikhathi sokusika. Lokhu kungabangela ukusikeka okungalingani, umonakalo wezinto zokwakha, noma ngisho nokuguguleka kwama-blade uma umklamo womphetho ungafaneleki esakhiweni sekhadibhodi.

●Ukuguquka noma Ukugoba

Ikhadibhodi elincane lingaguquguquka noma ligobe ngaphansi kwengcindezi nokushisa okukhiqizwa ngesikhathi sokusika. Lokhu kungafaka engcupheni ukunemba kokusikwa kanye nekhwalithi yomkhiqizo wokugcina.

●Ukukhiqizwa Kothuli Nokungcola

Ikhadibhodi elisika kancane livame ukukhiqiza uthuli oluncane noma imfucumfucu, enganqwabelana ezinsikeni noma ngaphakathi komshini wokusika. Lokhu kwakheka kungaphazamisa ukunemba kokusika futhi kudinge ukuhlanzwa njalo.

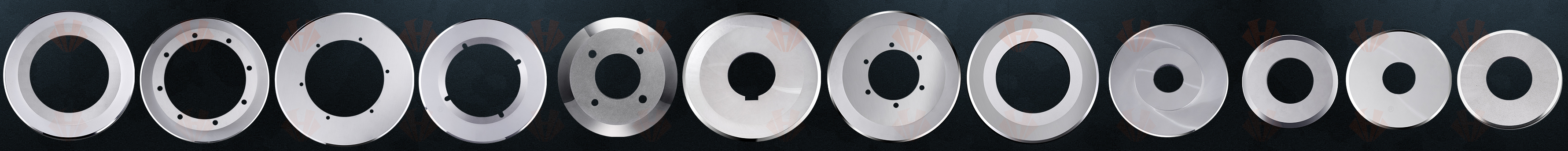

Izidingo zama-Tungsten Carbide Slitting Blades

Uma ubhekana nalokhuIzinselelo ezingenhla kanye nokuqinisekisa ukunqunywa okuphumelelayo kwekhadibhodi eboshiwe ene-grammage ephansi, ama-slitting blades e-tungsten carbide kumele abe nezakhiwo nezici ezilandelayo:

Ubukhali Obungavamile

Ama-blade kumele abe bukhali kakhulu ukuze akhiqize ukusikeka okuhlanzekile nokunembile ngaphandle kokudabula izinto ezincane. Uhlangothi olubukhali lunciphisa amandla okusika adingekayo, okunciphisa ingozi yokuklebhula noma yokuguqula ikhadibhodi.

Ukuqina Okuphezulu Nokumelana Nokugqoka

Ubulukhuni be-tungsten carbide obuyimvelo buyenza ibe yindawo ekahle yokusika izinto ezirhabaxa njengekhadibhodi eligoqiwe. Ukuze kusetshenziswe ama-braids aphansi, ama-blades kumele agcine ubukhali bawo ngokuhamba kwesikhathi, adinga izinga le-carbide elisezingeni eliphezulu kanye nokumelana okuhle kakhulu nokuguguleka ukuze kuncishiswe imvamisa yokulola noma yokushintshwa.

I-Optimized Edge Geometry

Unqenqema lokusika lwe-blade kufanele luhlelwe ngezinto ezincane. Isibonelo, unqenqema oluncane olune-radius encane (isb., 5–10 µm) luqinisekisa ukunemba, kanti unqenqema oluyindilinga kancane (isb., 15–20 µm) lungasiza ekusabalaliseni amandla futhi luvimbele ukudabuka. I-geometry incike ekujiyeni kwekhadibhodi kanye nokusethwa kokuqhekeka.

Ukungqubuzana Okuphansi Nokukhiqiza Ukushisa

Ukushisa okweqile kungagoba noma kulimaze ikhadibhodi elincane. Ama-blade kufanele abe nezindawo ezicwebezelisiwe noma izembozo, njenge-Titanium Nitride (TiN), ukuze kuncishiswe ukungqubuzana nokwakheka kokushisa ngesikhathi sokusika, kugcinwe ubuqotho bento.

Ukuphathwa Kokungabonakali

Nakuba i-tungsten carbide iqinile, nayo iyaphuka. Ama-blade kumele afakwe ngokucophelela futhi abekwe emshinini wokusika ukuze kugwenywe ukuqhekeka noma ukuqhekeka, ikakhulukazi ngesikhathi sokusebenza ngesivinini esikhulu.

Ukuhambisana Komshini

Ama-blade kumele afane nemininingwane yomshini wokusika (isb., usayizi, ukuma, kanye nendlela yokufaka). Imishini ehlukene, njengaleyo evela ku-BHS noma ku-Fosber, ingadinga ukwakheka kwama-blade athile ukuqinisekisa ukusebenza kahle.

Ukuqina Kokusebenza Okuqhubekayo

Ekukhiqizweni komthamo omkhulu, ama-blade adinga ukumelana nokusetshenziswa isikhathi eside ngaphandle kokulahlekelwa ukusebenza kahle. Ukuqina kwe-tungsten carbide kusekela lokhu, kodwa ukwakheka kwama-blade kumele kubhekane nezinselele ezihlukile zekhadibhodi elinobukhulu obuphansi ukuze kugcinwe ukusebenza kahle.

Ukusika ikhadibhodi eligoqekile elinesisindo esincane kuletha izinselele ezifana nokuklebhuka, ukufiphala kwama-blade, kanye nokuguqulwa kwezinto ngenxa yobukhulu balo obuncane nobulula.

Ama-blade okusika e-tungsten carbide kumele abe abukhali kakhulu, angagugi, futhi aklanywe nge-geometry enqenqemeni elungiselelwe ukubhekana nalezi zinkinga ngempumelelo. Ngaphezu kwalokho, ukunciphisa ukungqubuzana nokuqinisekisa ukuhambisana nomshini wokusika kubalulekile ekufinyeleleni ukusika kwekhwalithi ephezulu nokugcina ukusebenza kahle kokukhiqiza. Ngokuhlangabezana nalezi zidingo, abakhiqizi banganqoba izinkinga ezivamile futhi baqinisekise ukusebenza okuthembekile ekucubunguleni amakhadibhodi ahlanganisiwe ane-grammage ephansi.

Kungani Ukhethe iChengduhuaxin Carbide?

I-Chengduhuaxin Carbide ivelele emakethe ngenxa yokuzibophezela kwayo ekhwalithini nasekusunguleni izinto ezintsha. Ama-blade abo ekhaphethi e-tungsten carbide kanye nama-blade e-tungsten carbide aklanyelwe ukusebenza kahle kakhulu, anikeza abasebenzisi amathuluzi ahlinzeka ngokusika okuhlanzekile nokunembile ngenkathi ebekezelela ubunzima bokusetshenziswa kakhulu kwezimboni. Ngokugxila ekuqineni nasekusebenzeni kahle, ama-blade e-Chengduhuaxin Carbide anikeza ikhambi elifanele izimboni ezidinga amathuluzi okusika anokwethenjelwa.

I-CHENGDU HUAXIN CEMENTED CARBIDE CO.,LTD ingumhlinzeki ochwepheshe kanye nomkhiqizi weimikhiqizo ye-tungsten carbide,njengemimese yokufaka i-carbide yokusebenza ngokhuni, i-carbideimimese eyindilingangobaizinduku zokuhlunga ugwayi nogwayi, imimese eyindilinga ukusika amakhadibhodi ane-corugat,ama-razor blades/ama-slotted blades anezimbobo ezintathu ukupakisha, iteyipu, ukusika ifilimu encane, ama-fiber cutter blades embonini yezindwangu njll.

Njengoba sekuyiminyaka engaphezu kwengu-25 sithuthukisa imikhiqizo yethu, ithunyelwe kwamanye amazwe e-US A, Russia, South America, India, Turkey, Pakistan, Australia, Southeast Asia njll. Ngekhwalithi enhle kakhulu namanani ancintisanayo, isimo sethu sengqondo sokusebenza kanzima kanye nokuphendula kuyavunyelwa amakhasimende ethu. Futhi singathanda ukwakha ubudlelwano obusha bebhizinisi namakhasimende amasha.

Xhumana nathi namuhla futhi uzojabulela izinzuzo zekhwalithi enhle kanye nezinsizakalo ezivela emikhiqizweni yethu!

Imibuzo evamile yamakhasimende kanye nezimpendulo ze-Huaxin

Lokho kuncike enanini, ngokuvamile izinsuku ezi-5-14. Njengomkhiqizi wezinsika zezimboni, i-Huaxin Cement Carbide ihlela ukukhiqizwa ngama-oda kanye nezicelo zamakhasimende.

Ngokuvamile amasonto ama-3-6, uma ucela imimese yomshini eyenziwe ngokwezifiso noma ama-blade ezimboni angekho esitokweni ngesikhathi sokuthenga. Thola i-Sollex Purchase & Delivery Conditions lapha.

uma ucela imimese yomshini eyenziwe ngokwezifiso noma ama-blade ezimboni angekho esitokweni ngesikhathi sokuthenga. Thola Izimo Zokuthenga Nokulethwa ze-Sollexlapha.

Ngokuvamile i-T/T, i-Western Union...idiphozithi kuqala, Wonke ama-oda okuqala avela kumakhasimende amasha akhokhelwa kusengaphambili. Ama-oda engeziwe angakhokhwa nge-invoyisi...Xhumana nathiukwazi okwengeziwe

Yebo, xhumana nathi, imimese yezimboni iyatholakala ngezindlela ezahlukene, kufaka phakathi imimese enesitsha esiphezulu, imimese eyindilinga engezansi, imimese enezinyo ezigobile/ezinamazinyo, imimese ebhoboza nxazonke, imimese eqondile, imimese ye-guillotine, imimese ecijile, imimese ye-razor engunxande, kanye nemimese ye-trapezoidal.

Ukuze sikusize uthole i-blade engcono kakhulu, i-Huaxin Cement Carbide ingakunikeza ama-blade amaningana amasampula ongawahlola ekukhiqizweni. Ukuze usike futhi uguqule izinto eziguquguqukayo njengefilimu yepulasitiki, i-foil, i-vinyl, iphepha, nokunye, sinikeza ama-blade okuguqula kufaka phakathi ama-slitter blade anezikhala kanye nama-razor blade anezikhala ezintathu. Sithumelele umbuzo uma unentshisekelo kuma-blade omshini, futhi sizokunikeza isipho. Amasampula emimese eyenziwe ngokwezifiso awatholakali kodwa wamukelekile uku-oda inani elincane kakhulu le-oda.

Kunezindlela eziningi ezizokwandisa isikhathi eside kanye nokuphila kweshelufu kwemimese yakho yezimboni kanye nama-blade esitokweni. Xhumana nathi ukuze wazi ukuthi ukupakishwa okufanele kwemimese yomshini, izimo zokugcina, umswakama kanye nokushisa komoya, kanye nokwembozwa okwengeziwe kuzovikela imimese yakho futhi kugcine ukusebenza kwayo kokusika.

Isikhathi sokuthunyelwe: Juni-20-2025