Amathuluzi e-carbide afakwe usimende abusa kakhulu kumathuluzi okugaya e-CNC. Kwamanye amazwe, amathuluzi okujika angaphezu kuka-90% kanye namathuluzi okugaya angaphezu kuka-55% enziwe nge-carbide efakwe usimende. Ngaphezu kwalokho, i-carbide efakwe usimende ivame ukusetshenziswa ukukhiqiza amathuluzi ajwayelekile njengemishini yokubhoboza kanye nemishini yokusika ubuso. Ukusetshenziswa kwe-carbide efakwe usimende kuyanda nakumathuluzi ayinkimbinkimbi njengemishini yokulungisa, imishini yokugaya yokugcina, imishini yokusika yegiya ye-modulus ephakathi nenkulu yokulungisa izindawo zamazinyo eziqinile, kanye nama-broaches. Ukusebenza kahle kokusika kwamathuluzi e-carbide afakwe usimende kuphindwe kahlanu kuya kasishiyagalombili kunamathuluzi ensimbi esheshayo (i-HSS). Inani lensimbi elisusiwe ngeyunithi ngayinye yokuqukethwe kwe-tungsten cishe liphindwe kahlanu kunele-HSS. Ngakho-ke, ukusebenzisa kabanzi i-carbide efakwe usimende njengethuluzi kungenye yezindlela eziphumelela kakhulu zokusebenzisa izinsiza ngempumelelo, ukuthuthukisa umkhiqizo wokusika, kanye nokuthuthukisa izinzuzo zomnotho.

Ukuhlukaniswa Kwezinto Zamathuluzi E-Carbide Ene-Cemented

Ngokusekelwe ekwakhiweni kwamakhemikhali okuyinhloko, i-carbide eqinisiwe ingahlukaniswa ibe yi-carbide eqinisiwe esekelwe ku-tungsten carbide kanye ne-carbide eqinisiwe esekelwe ku-titanium carbonitride (Ti(C,N)), njengoba kuboniswe kuThebula 3-1.

I-carbide eyenziwe nge-cemented esekelwe ku-tungsten carbide ihlanganisa:

I-Tungsten-cobalt (YG)

I-Tungsten-cobalt-titanium (YT)

Ngama-carbide angavamile engeziwe (YW)

Uhlobo ngalunye lunezinzuzo nezinkinga zalo. Ama-carbide engeziwe afaka i-tungsten carbide (WC), i-titanium carbide (TiC), i-tantalum carbide (TaC), i-niobium carbide (NbC), njll., kanti i-cobalt (Co) iyisigaba sokubopha insimbi esivame ukusetshenziswa.

I-carbide eqinisiwe esekelwe ku-titanium carbonitride ngokuyinhloko iqukethe i-TiC (eminye enezinye i-carbide noma i-nitrides ezengeziwe), ene-molybdenum (Mo) kanye ne-nickel (Ni) njengezigaba zokubopha zensimbi ezisetshenziswa kakhulu.

Ngokusekelwe kubukhulu bezinhlamvu, i-carbide eqinisiwe ingahlukaniswa ibe yi:

I-carbide evamile eyenziwe ngosimende

I-carbide eqiniswe kahle

I-carbide eyenziwe nge-cemented ultrafine

Ngokusho kwe-GB/T 2075—2007, izimpawu zezinhlamvu yilezi ezilandelayo:

I-HW: I-carbide engagqokwanga equkethe ikakhulukazi i-tungsten carbide (WC) enobukhulu bezinhlamvu obungu-≥1μm

I-HF: I-carbide engagqokwanga equkethe ikakhulukazi i-tungsten carbide (WC) enobukhulu bezinhlamvu obungaphansi kwe-1μm

I-HT: I-carbide engagqokwanga equkethe i-titanium carbide (TiC) noma i-titanium nitride (TiN) noma kokubili (eyaziwa nangokuthi i-cermet)

I-HC: Ama-carbide afakwe ukhonkolo okukhulunywe ngawo ngenhla anesembozo

I-International Organisation for Standardization (ISO) ihlukanisa ukusika ama-carbide aqinisiwe ngezigaba ezintathu:

Ikilasi le-K (K10 kuya ku-K40):

Ilingana nekilasi le-YG laseShayina (ikakhulukazi elakhiwe yi-WC-Co)

Ikilasi le-P (P01 kuya ku-P50):

Ilingana nekilasi le-YT laseShayina (ikakhulukazi elakhiwe yi-WC-TiC-Co)

Ikilasi le-M (M10 kuya ku-M40):

Ilingana nekilasi le-YW laseShayina (ikakhulukazi elakhiwe yi-WC-TiC-TaC(NbC)-Co)

Amabanga esigaba ngasinye amelelwa yinombolo ephakathi kuka-01 no-50, ekhombisa uchungechunge lwe-alloys kusukela ebunzimeni obukhulu kakhulu kuya ebunzimeni obukhulu kakhulu, ukuze kukhethwe izinqubo ezahlukene zokusika kanye nezimo zomshini wezinto zokusebenza ezahlukene. Uma kudingeka, ikhodi ephakathi ingafakwa phakathi kwamakhodi amabili okuhlukanisa aseduze, njenge-P15 phakathi kwe-P10 ne-P20, noma i-K25 phakathi kwe-K20 ne-K30, kodwa kungabi ngaphezu kweyodwa. Ezimweni ezikhethekile, ikhodi yokuhlukanisa ye-P01 ingahlukaniswa ngokungeziwe ngokungeza enye idijithi ehlukaniswe yiphuzu ledesimali, njenge-P01.1, P01.2, njll., ukuze kuhlukaniswe kabanzi ukumelana nokuguguleka kanye nokuqina kwezinto zokuqeda imisebenzi.

Ukusebenza Kwezinto Zamathuluzi E-Carbide Ene-Cemented

1. UkuqinaI-carbide enosimende iqukethe inani elikhulu lama-carbide aqinile (njenge-WC, i-TiC), okwenza ubulukhuni bayo bube phezulu kakhulu kunobezinto zensimbi ezinesivinini esikhulu. Uma ubulukhuni be-carbide enosimende buphakeme, kulapho ukumelana kwayo nokuguguleka kungcono khona, okuvame ukuba phezulu kakhulu kunokwensimbi enesivinini esikhulu.

Uma okuqukethwe kwesigaba se-cobalt binder kuphakeme, kulapho ubulukhuni be-alloy buncipha khona.

Njengoba i-TiC ilukhuni kune-WC, ama-alloy e-WC-TiC-Co anobulukhuni obuphezulu kune-alloy ye-WC-Co. Uma okuqukethwe kwe-TiC kuningi, kulapho ubulukhuni buphakama khona.

Ukwengeza i-TaC kuma-alloy e-WC-Co kwandisa ubulukhuni cishe ngama-HV angu-40 kuya ku-100; ukwengeza i-NbC kwandisa ubulukhuni ngama-HV angu-70 kuya ku-150.

2. Amandla Amandla okugobeka kwe-carbide esimende acishe abe yi-1/3 kuya ku-1/2 kuphela njengalawo ezinto zensimbi ezisheshayo.

Uma okuqukethwe yi-cobalt kuphakeme, kulapho amandla e-alloy ephakama khona.

Ama-alloy aqukethe i-TiC anamandla aphansi kunalawo angenayo i-TiC; uma okuqukethwe kwe-TiC kuningi, amandla aphansi.

Ukwengeza i-TaC ku-WC-TiC-Co cemented carbide kwandisa amandla ayo okuguquguquka futhi kuthuthukisa kakhulu ukumelana komkhawulo wamanje ekuqhekekeni nasekuqhekekeni. Njengoba okuqukethwe yi-TaC kukhuphuka, amandla okukhathala nawo ayathuthuka.

Amandla okucindezela e-carbide esimende aphezulu ngo-30% kuya ku-50% kunawensimbi yesivinini esikhulu.

3. UkuqinaUkuqina kwe-carbide esimende kuphansi kakhulu kunokwensimbi eshesha kakhulu.

Ama-alloy aqukethe i-TiC anokuqina okuphansi kunalawo angenayo i-TiC; njengoba okuqukethwe yi-TiC kukhuphuka, ukuqina kuyancipha.

Kuma-alloy e-WC-TiC-Co, ukwengeza inani elifanele le-TaC kungandisa ukuqina cishe ngo-10% ngenkathi kugcinwa ukumelana nokushisa kanye nokumelana nokuguguleka.

Ngenxa yokuqina kwayo okuphansi, i-carbide eqinisiwe ayifaneleki ezimweni ezinezithiyo noma ukudlidliza okunamandla, ikakhulukazi ngesivinini esiphansi sokusika lapho ukunamathela nokuqhekeka kukhulu khona.

4. Izakhiwo Zomzimba ZokushisaUkushisa kwe-carbide eqinisiwe kuphakeme cishe ngokuphindwe kabili kuya kathathu kunokwensimbi enesivinini esikhulu.

Njengoba ukuqhutshwa kwe-TiC ekushiseni kuphansi kune-WC, ama-alloy e-WC-TiC-Co anokuqhutshwa kwe-thermal okuphansi kune-WC-Co. Uma okuqukethwe kwe-TiC kuningi, kulapho ukuqhutshwa kwe-thermal kuba kubi khona.

5. Ukumelana Nokushisa I-carbide eyenziwe ngosimende inokumelana nokushisa okuphezulu kakhulu kunensimbi yesivinini esikhulu futhi ingasika ku-800 kuya ku-1000°C ngokumelana okuhle nokuguqulwa kwepulasitiki emazingeni okushisa aphezulu.

Ukwengeza i-TiC kwandisa ubulukhuni obuphezulu. Njengoba izinga lokushisa lokuthambisa le-TiC liphakeme kune-WC, ubulukhuni be-WC-TiC-Co alloys buncipha kancane ngokushisa kune-WC-Co alloys. Uma i-TiC iningi futhi i-cobalt incane, kulapho ukwehla kuncipha khona.

Ukwengeza i-TaC noma i-NbC (enezinga lokushisa eliphakeme lokuthambisa kune-TiC) kwandisa kakhulu ubulukhuni namandla okushisa okuphezulu.

6. Izakhiwo ZokunamathelaIzinga lokushisa lokunamathela le-carbide eqinisiwe liphakeme kunelensimbi yesivinini esikhulu, okwenza ukuthi imelane kangcono nokuguguleka kokunamathela.

Izinga lokushisa lokunamathela kweCobalt ngensimbi liphansi kakhulu kunele-WC; njengoba okuqukethwe yi-cobalt kukhuphuka, izinga lokushisa lokunamathela liyancipha.

Izinga lokushisa lokunamathela kwe-TiC liphakeme kune-WC, ngakho-ke ama-alloy e-WC-TiC-Co anezinga lokushisa eliphakeme lokunamathela (cishe libe ngu-100°C ngaphezulu) kune-alloy ye-WC-Co. I-TiO2 eyakhiwe emazingeni okushisa aphezulu ngesikhathi sokusika inciphisa ukunamathela.

I-TaC ne-NbC zinamazinga okushisa aphezulu okunamathela kune-TiC, okuthuthukisa izakhiwo zokulwa nokunamathela. Ukusondelana kwe-TaC nezinto zokusebenza kuyingxenye encane nje uma kuqhathaniswa nezingxenye ezimbalwa kweshumi zama-WC.

7. Ukuzinza KwamakhemikhaliUkumelana nokuguguleka kwamathuluzi e-carbide aqinisiwe kuhlobene kakhulu nokuqina kwawo ngokomzimba nangokwekhemikhali emazingeni okushisa okusebenza.

Izinga lokushisa le-oxidation le-carbide eqinisiwe liphakeme kunelensimbi eshesha kakhulu.

Izinga lokushisa le-oxidation le-TiC liphakeme kakhulu kune-WC, ngakho-ke ama-alloy e-WC-TiC-Co athola isisindo esincane se-oxidation emazingeni okushisa aphezulu kune-WC-Co alloys; lapho i-TiC iningi, kulapho ukumelana kwe-oxidation kuqina khona.

Izinga lokushisa le-oxidation le-TaC liphakeme kakhulu kune-WC, kanti ama-alloy ane-TaC ne-NbC athuthukise ukumelana ne-oxidation yokushisa okuphezulu. Kodwa-ke, okuqukethwe okuphezulu kwe-cobalt kwenza i-oxidation ibe lula.

Kungani Ukhethe iChengduhuaxin Carbide?

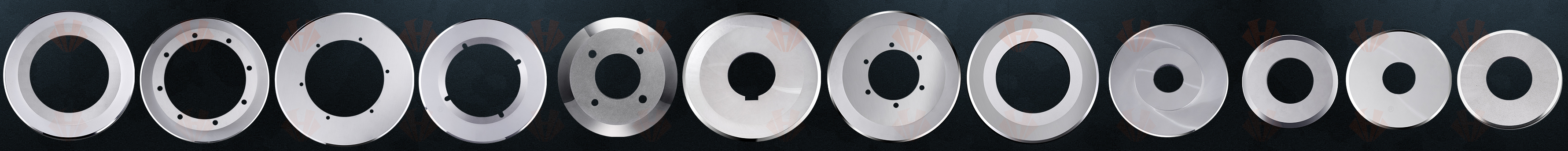

I-Chengduhuaxin Carbide ivelele emakethe ngenxa yokuzibophezela kwayo ekhwalithini nasekusunguleni izinto ezintsha. Ama-blade abo ekhaphethi e-tungsten carbide kanye nama-blade e-tungsten carbide aklanyelwe ukusebenza kahle kakhulu, anikeza abasebenzisi amathuluzi ahlinzeka ngokusika okuhlanzekile nokunembile ngenkathi ebekezelela ubunzima bokusetshenziswa kakhulu kwezimboni. Ngokugxila ekuqineni nasekusebenzeni kahle, ama-blade e-Chengduhuaxin Carbide anikeza ikhambi elifanele izimboni ezidinga amathuluzi okusika anokwethenjelwa.

I-CHENGDU HUAXIN CEMENTED CARBIDE CO.,LTD ingumhlinzeki ochwepheshe kanye nomkhiqizi weimikhiqizo ye-tungsten carbide,njengemimese yokufaka i-carbide yokusebenza ngokhuni, i-carbideimimese eyindilingangobaizinduku zokuhlunga ugwayi nogwayi, imimese eyindilinga ukusika amakhadibhodi ane-corugat,ama-razor blades/ama-slotted blades anezimbobo ezintathu ukupakisha, iteyipu, ukusika ifilimu encane, ama-fiber cutter blades embonini yezindwangu njll.

Njengoba sekuyiminyaka engaphezu kwengu-25 sithuthukisa imikhiqizo yethu, ithunyelwe kwamanye amazwe e-US A, Russia, South America, India, Turkey, Pakistan, Australia, Southeast Asia njll. Ngekhwalithi enhle kakhulu namanani ancintisanayo, isimo sethu sengqondo sokusebenza kanzima kanye nokuphendula kuyavunyelwa amakhasimende ethu. Futhi singathanda ukwakha ubudlelwano obusha bebhizinisi namakhasimende amasha.

Xhumana nathi namuhla futhi uzojabulela izinzuzo zekhwalithi enhle kanye nezinsizakalo ezivela emikhiqizweni yethu!

Imibuzo evamile yamakhasimende kanye nezimpendulo ze-Huaxin

Lokho kuncike enanini, ngokuvamile izinsuku ezi-5-14. Njengomkhiqizi wezinsika zezimboni, i-Huaxin Cement Carbide ihlela ukukhiqizwa ngama-oda kanye nezicelo zamakhasimende.

Ngokuvamile amasonto ama-3-6, uma ucela imimese yomshini eyenziwe ngokwezifiso noma ama-blade ezimboni angekho esitokweni ngesikhathi sokuthenga. Thola i-Sollex Purchase & Delivery Conditions lapha.

uma ucela imimese yomshini eyenziwe ngokwezifiso noma ama-blade ezimboni angekho esitokweni ngesikhathi sokuthenga. Thola Izimo Zokuthenga Nokulethwa ze-Sollexlapha.

Ngokuvamile i-T/T, i-Western Union...idiphozithi kuqala, Wonke ama-oda okuqala avela kumakhasimende amasha akhokhelwa kusengaphambili. Ama-oda engeziwe angakhokhwa nge-invoyisi...Xhumana nathiukwazi okwengeziwe

Yebo, xhumana nathi, imimese yezimboni iyatholakala ngezindlela ezahlukene, kufaka phakathi imimese enesitsha esiphezulu, imimese eyindilinga engezansi, imimese enezinyo ezigobile/ezinamazinyo, imimese ebhoboza nxazonke, imimese eqondile, imimese ye-guillotine, imimese ecijile, imimese ye-razor engunxande, kanye nemimese ye-trapezoidal.

Ukuze sikusize uthole i-blade engcono kakhulu, i-Huaxin Cement Carbide ingakunikeza ama-blade amaningana amasampula ongawahlola ekukhiqizweni. Ukuze usike futhi uguqule izinto eziguquguqukayo njengefilimu yepulasitiki, i-foil, i-vinyl, iphepha, nokunye, sinikeza ama-blade okuguqula kufaka phakathi ama-slitter blade anezikhala kanye nama-razor blade anezikhala ezintathu. Sithumelele umbuzo uma unentshisekelo kuma-blade omshini, futhi sizokunikeza isipho. Amasampula emimese eyenziwe ngokwezifiso awatholakali kodwa wamukelekile uku-oda inani elincane kakhulu le-oda.

Kunezindlela eziningi ezizokwandisa isikhathi eside kanye nokuphila kweshelufu kwemimese yakho yezimboni kanye nama-blade esitokweni. Xhumana nathi ukuze wazi ukuthi ukupakishwa okufanele kwemimese yomshini, izimo zokugcina, umswakama kanye nokushisa komoya, kanye nokwembozwa okwengeziwe kuzovikela imimese yakho futhi kugcine ukusebenza kwayo kokusika.

Isikhathi sokuthunyelwe: Julayi-23-2025